Do you know how grocery store cash register conveyor belts work? It works exactly the same, but in a large factory where multiple products are produced. Because of its strength, long durability and heavy carrying ability without the use? PVC conveyor belts are an ideal solution for factories. These conveyor belts are manufactured from a form of plastic known as PVC (polyvinyl chloride). The expression of this special material makes the belts durable and ideal for any sort of labor.

PVC conveyor belts are most common in many factories, even for food processing. They are not affected by oil, fat or any chemicals which can spill on them. This is a significant feature in food factories in terms of hygiene and safety. They also perform excellently in extremely hot or cold environments, making them ideal for use in applications such as baking bread in high-temperature ovens or moving frozen foods around cold storage areas. PVC conveyor belts are universally applicable; generally speaking, not only used in food factories but also found in most industries such as mining, paper-making and printing. Very capable in weight and speed, they fulfil a number of uses.

In addition to this, the PVC conveyor belts are able to provide a constant speed driving when conveying any product. This is extremely important to ensure that everything is being done correctly. It is also important to ensure that products do not get broken if it moves much faster or the process does not get delayed if it moves very slow. Many PVC conveyor can be designed to run at a specific speed, which will prove useful when trying to guarantee that products are always running and being produced safely and accurately. With this consistency, factories are able to ensure superior quality control and make certain each item being produced meets the required benchmarks.

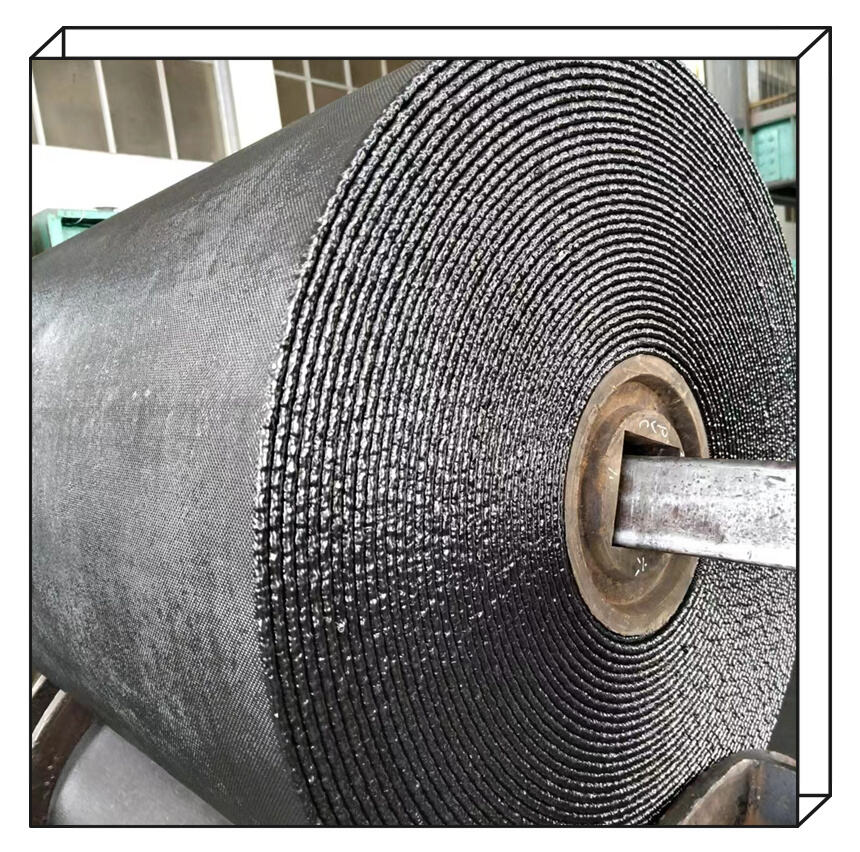

There are so many types of Pvc conveyor belt, When you choose one, Choosing the correct one in line with your business requirement is extremely important. Which conveyor belt you select varies according to your products and factory conditions. PVC conveyor belts come in several different styles: flat, bumped-up cleats, and raised ridges, for example. Certain belts can be smooth, while others are rough. What you're trying to move will dictate what's best.

In example, if you need to transport boxes or packages the PVC conveyor belt is an affective flat selection in providing a stable surface. Alternatively, fruits and vegetables are also better moved with a ridged PVC conveyor belt, which has alternating high and low points arranged crossways to help hold the fruit or vegetable up when they are being transported. Also, you should consider how robust the conveyor belt must be and what is the thickness as well as width of it. Why are these factors important — obviously it means those will influence how well the conveyor belt can serve you be carrying items that needs to move.

PVC conveyor belts they are just like any other machine which exerted effort, and need to be maintained for longer life. And one of the most vital aspects involved when maintaining them is that we should know about making sure to clean up conveyors on a regular basis. This aids in clearing out grime, gunk or buildup that may settle over the period of time. A clean belt can reduce damage and keep the belt running smoothly, which is vital to maximizing efficiency in your factory.

The second aspect of maintenance is the check on the tightness of the conveyor belt. With time, the belt may loosen or stretch and this can change how well it functions. When you want to look into helping when needed, turn off the conveyor belt and see if you can move it with your hand. It should not move more than an inch, with a little trial and error you will learn if the wrap is too loose if it moves. Maintaining proper tension is critical since this will enable the conveyor belt to perform its function properly and effectively.