Have you heard of the PVC 1250S conveyor? Perhaps in contradiction to the sounding of that, it simply means a conveyor that is so tough and built for emergency work. With Karrier conveyor belts, the PVC 1250S carries materials conveniently from one point to another. Find out about this type of belt and why it is far different from all other belts, as well learn how heavy items are transported with these.

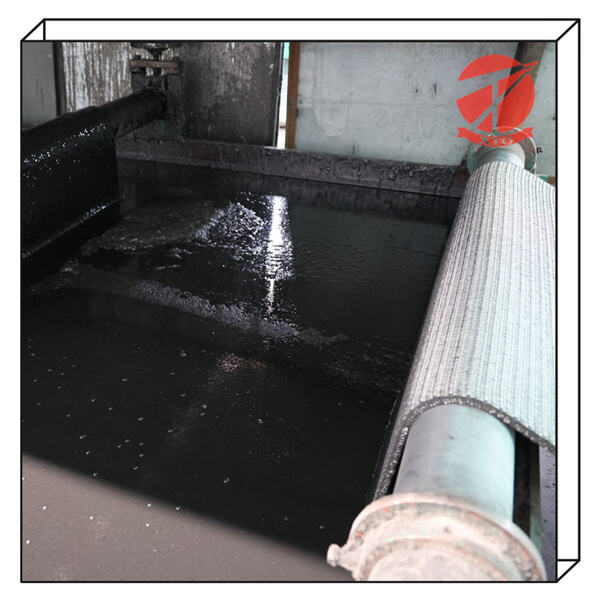

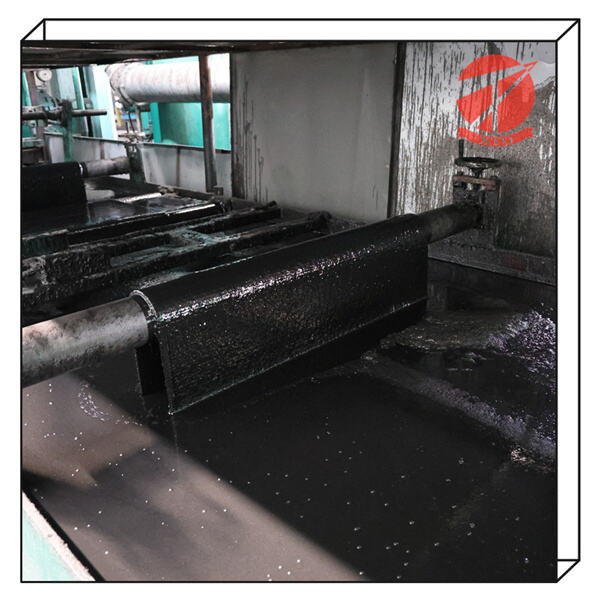

If you have to move heavy equipment (such as large boxes or rocks) a conveyor belt would do, it will take care of all those pounds. For such a case, we have PVC 1250S conveyor belts! Constructed out of a special kind of strong PVC material, these belts are not like those that wear as well quickly. With that tough material, they handle even the heaviest loads without breaking or twisting to become useless. That means that these conveyor belts can handle anything, even the widest of objects safely and quickly.

The PVC 1250S belts are ideal for use a multitude of different temperatures. Little else you remember is their sweat, or shiver. It is particularly important for work that is carried out in locations with extremely hot temperatures, while it could be cold elsewhere. They are also resistant to chemicals. Therefore suitable where things require to move in different conditions like mining and factories or chemicals are utilized during production. THE SOLITARY AND THE STOUT HEART!

This PVC 1250S conveyer belt is also easy to take care of, which means it will not require a lot to keep on working properly. This means you will not need to do much of fixing and maintaining on them. Low On Maintenance seems pretty reasonable,however they are great task machines and get the job done. This makes them ideal for material handling. They do break down fewer and many not regularly so need repair. This ultimately saves company time but also money which they can spend on growing and delivering their services rather than repairing hardware.

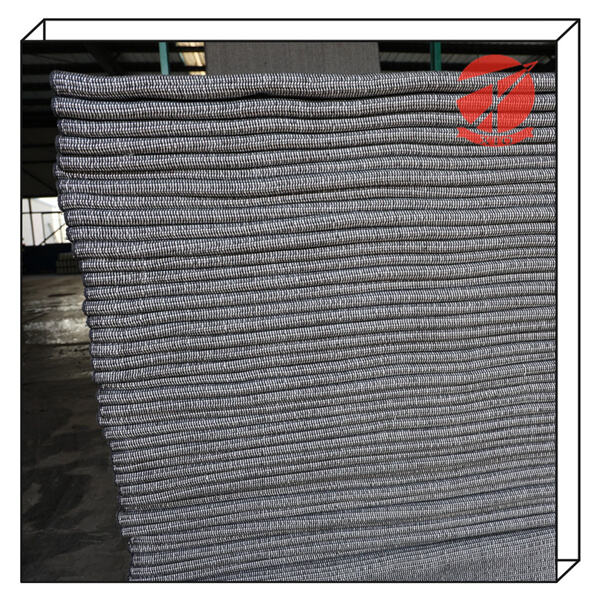

Have you ever seen a conveyor belt lumpy like this? In environments which are not serenely planar, it is oftentimes impossible to migrate objects without having them drag. But the PVC 1250S conveyor belts are flat surfaced belt, for this reason materials to be transported follow a concave path. In locations that require severe precision — like manufacturing facilities for food or car parts, a level surface is necessary. You need to have things safely and properly moved from one place to another, so you just HAVE TO BUY these conveyor belts for your warehouse.

Finally, the very last one of many interesting characteristics with regards to PVC 1250S conveyor straps would likely be associated how and also these are put together for being incorporated into distinct techniques. These can range from… more favorable for one job and material than another, to help make them as performant as possible. Belts can be made wider or narrower to fit a larger area, they may have different textures for more traction and some come with bumps and ridges that will not let items slide. This is the flexibility, which makes them good for lots of applications across many possible industries.