기름은 미끄러지고 지저분한 물질로, 접촉하지 않아야 할 물체와 접촉하면 다양한 문제를 일으킬 수 있습니다. 여러분은 기름이 매우 미끄럽고 위험한 표면이라는 것을 알고 있을 것입니다. 이러한 이유들 때문에 많은 작업장에서는 파손 방지 스틸 코드 컨베이어 벨트와 같이 일반적인 문제입니다. 이런 독특한 벨트들은 기름뿐만 아니라 다른 액체에도 특별히 설계되어 있어 다양한 산업에서 유용하게 사용됩니다. 여기 기름에 강한 컨베이어 벨트가 제공하는 다채로운 이점에 대한 추가 정보, 사업 요구에 맞는 선택 방법 및 컨베이어 벨트를 더 오래 유지할 수 있도록 도와주는 몇 가지 관리 요령이 나와 있습니다.

오일 저항성 컨베이어 벨트는 많은 유용한 특징을 가지고 있습니다. 먼저, 그들의 가장 큰 장점 중 하나는 오일 손상을 방지할 수 있다는 것입니다. 이는 이러한 벨트가 고장 나기 쉽지 않고 오일 노출로 인해 손상되기 어렵다는 것을 의미합니다. 컨베이어 벨트는 많은 제조 과정에서 중요한 부분이므로这一点은 매우 중요합니다. 이러한 스틸 벨트 없이는 물체를 한 장소에서 다른 장소로 운반하는 것이 매우 어려워질 뿐만 아니라 생산도 멈출 수 있습니다.

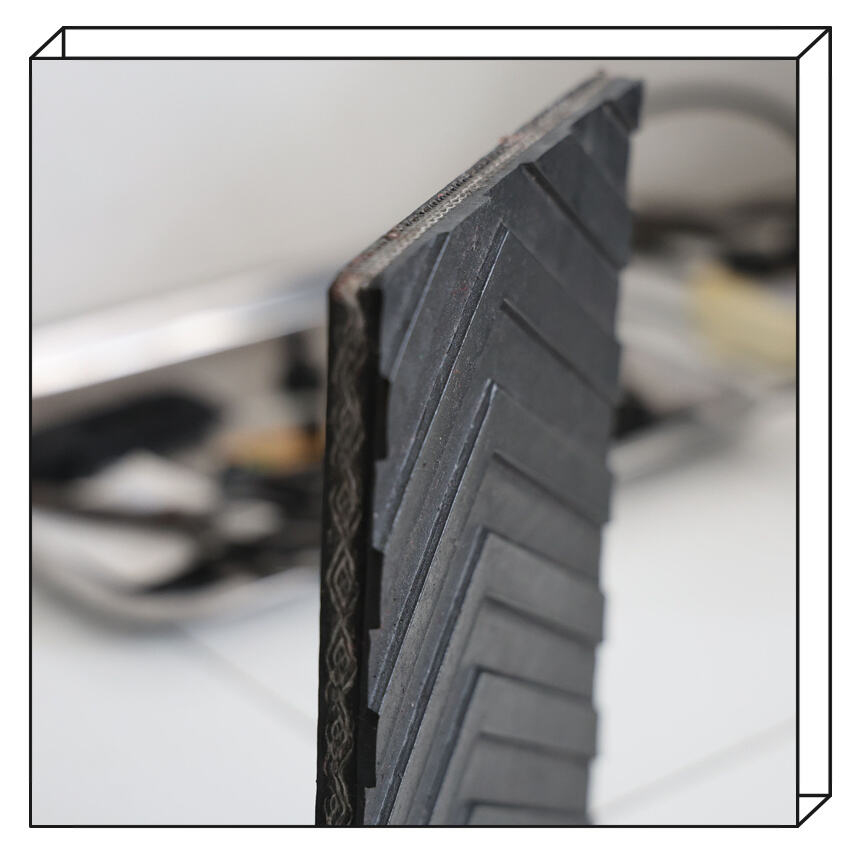

내구성이 있는 것을 갖는 또 다른 가장 중요한 이유는 조립라인 컨베이어 시스템 이 벨트들은 어떤 종류의摩耗에도 견딜 수 있도록 튼튼하게 만들어졌습니다. 특히 무거운 물질을 이동할 때 발생하는摩耗에 대비했습니다. 그 내구성은 다른 종류의 컨베이어 벨트보다 훨씬 더 오래 사용될 수 있음을 의미합니다. 이는 컨베이어 벨트 교체가 시간이 많이 걸리고, both fittings과 운영 중단에 대한 비용이 많이 드는 투자라는 점에서 매우 우수한 장점입니다. 기름에 강한 벨트는 기업이 장기적으로 비용을 절감하고, 공급 부족으로 인한 생산 과정의 중단 없이 운영할 수 있도록 도와줍니다.

비즈니스에 오일 저항성 컨베이어 벨트를 설치할 계획이라면 고려해야 할 몇 가지 중요한 사항이 있습니다. 먼저, 이동시킬 물질의 유형을 생각해 보십시오. 다양한 물질은 서로 다른 무게를 가지고 있으므로 무거운 물체를 이동시킬 경우 더 강한 벨트를 구입해야 할 수 있습니다. 산업용 용도가 무거운 금속 부품이나 큰 재료 가방을 포함한다면, 그 무게를 견디고 끊기지 않는 벨트가 필요합니다.

다른 고려사항은 벨트가 어떤 환경에서 사용될 것인가입니다. 벨트가 뜨거운 환경, 추운 환경 또는 마모성 화학물질이 있는 곳에서 사용될까요? 따라서 벨트가 직면할 극한 조건이 있을 경우, 이러한 손상을 견딜 수 있도록 설계된 고품질의 제조 벨트를 원해야 합니다. 이러한 전송벨트는 다양한 유형으로 제공되며, 귀하의 비즈니스에 가장 적합한 고유분지 내열 컨베이어 벨트를 산동 향통 고무과학사에서 구할 수 있습니다.

정비 필요 – 정비 계획을 세우는 것이 이상적이고, 점검, 청소 및 수리 일정을 잡는 것이 더 나은 관행입니다. 이러한 유지보수 계획은 전송벨트가 우수한 상태를 유지하도록 도와주고 갑작스러운 고장도 방지해 줄 것입니다.

식품 산업 - 음식은 소비되기 전에 명확한 과정을 거칩니다. 컨베이어 벨트는 씨앗 심기와 작물 수확에서 제품 포장까지 모든 것을 조율합니다. 컨베이어 시스템의 원활한 운영은 식품의 수확과 가공에 필수적입니다. 기름에 강한 벨트는 컨베이어가 부드럽게 작동하도록 돕습니다.