إنها في المصانع الكبيرة حيث تساعد الآلات على نقل الأشياء من النقطة أ إلى النقطة ب. هذه الآلات تُسمى أحزمة ناقلة. كانت شائعة جدًا في الصناعات لأنها تُستخدم لنقل الأجسام الثقيلة بسرعة وسهولة حتى يتم إنجاز العمل بشكل أسرع. بدون أحزمة ناقلة، يجب حمل الأشياء الثقيلة يدويًا، مما يجعل العملية أبطأ وأكثر إرهاقًا.

لكن كيف ستكون المصنع إذا كان الجو ساخنًا جدًا؟ السؤال 2: قد تتعرض أحزمة النقل التقليدية للتلف أو الانكسار عندما يكون الجو حارًا جدًا. الآن يمكن أن يصبح هذا مشكلة كبيرة لأن إذا توقفت أحزمة النقل عن العمل، فهذا سيبطئ عمل المصنع بالكامل. هنا يأتي دور شركة شاندونغ شيانغتونغ للصناعات المطاطية حزام ناقل ذو حبل فولاذي مضاد للتمزق لتغيير اللعبة. الآن وبعد أن عرفت لماذا تحتاج الأحزمة الناقلة عالية الحرارة في المصانع التي تعامل مع درجات حرارة مرتفعة أحيانًا، دعنا نوضح المزيد عنها!

عندما تعمل الآلات طوال اليوم، يمكن أن تصبح المصانع ساخنة جدًا. الأحزمة الناقلة التقليدية ليست مصممة لتحمل هذا المستوى من الحرارة. يمكن أن تذوب أو تتفكك هذه الأحزمة عند درجات حرارة مرتفعة، مما قد يؤدي إلى مشاكل أكبر في المصنع. الأحزمة الناقلة المقاومة للحرارة العالية فريدة من نوعها لأن درجة الحرارة يمكن أن تكون شديدة للغاية ومع ذلك فإنها تستمر في أداء عملها باستمرار في ظروف حارة. وهذا مهم لأنه يعني أن المصانع يمكن أن تستمر في العمل بسلاسة دون قلق بشأن توقف الآلات أو تعطلها.

الأحزمة الناقلة المقاومة للحرارة العالية رائعة لأنها غالبًا ما تكون قوية أيضًا. حسنًا، هذا يعني أنها تتحمل عبء العمل الشاق في ظروف غير مثالية لفترة طويلة. وأخيرًا وليس آخرًا، توفر الأحزمة الناقلة القوية للمصانع المال لأنها لن تحتاج إلى استبدال الأحزمة بشكل متكرر. إذا كان يجب شراء الأحزمة بشكل دوري، فقد يصبح الأمر مكلفًا جدًا لمصنع الإنتاج. وبالتالي، تُوفر المصانع المال عندما تستخدم أنظمة ناقلة لخطوط التجميع على مر السنين.

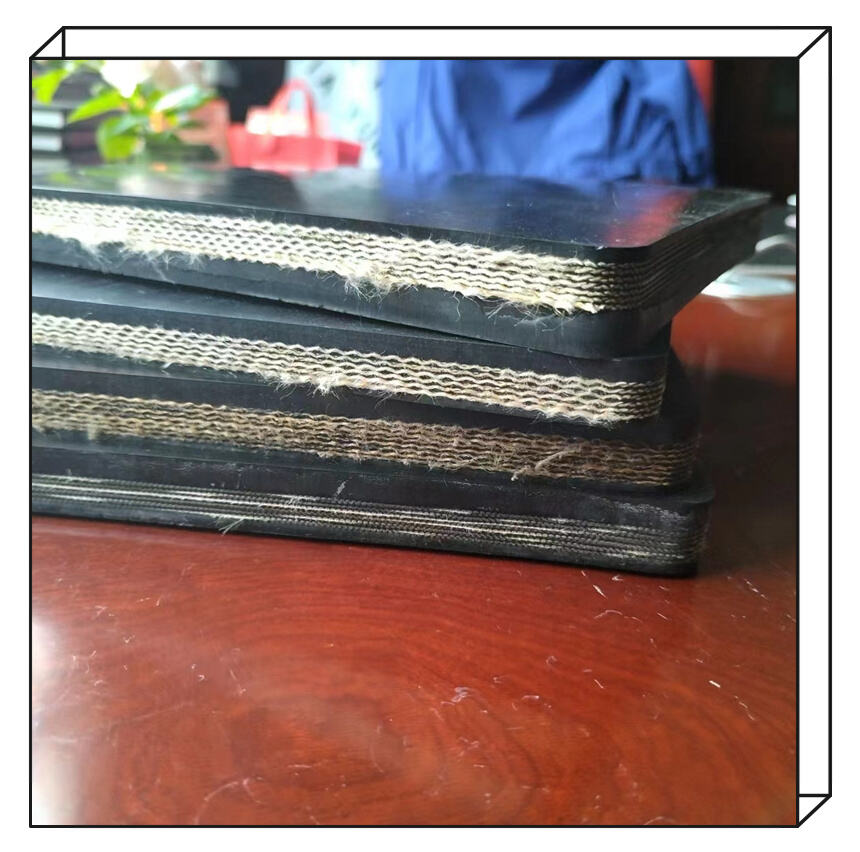

كما ناقشنا، تستخدم أحزمة النقل عند درجات الحرارة العالية موادًا محددة تتحمل تحت ظروف درجات الحرارة الشديدة. وهذا مهم لأنه يشير إلى أن الأحزمة يمكن أن تصمد لفترة طويلة رغم الاستخدام المكثف في بيئات ذات حرارة عالية. هذا هو أحد الفوائد الرئيسية للمصانع لأنها لن تنفق الكثير في استبدال أحزمة النقل كل بضعة أشهر أو حتى سنوات. بهذه الطريقة، يمكنهم التركيز بشكل كامل على العمل مع إنتاجية أعلى دون أي انقطاع في سير العمليات.

عندما تتوقف الآلات في المصنع، سيكون هناك كارثة. ليس فقط يجعل العمل يستغرق وقتًا أطول للإتمام، ولكنه أيضًا يضع الموظفين تحت الخطر. حزام النقل عالي الحرارة يحمي الآلات من الحرارة الزائدة في بيئة التشغيل التي قد تسبب تعطل العمليات. يمكن للموظفين العمل دون انقطاع، ويمكن للمصانع الاستمرار في إنتاج السلع بسرعة.* وعندما يتم كل شيء معًا بشكل جيد، فإنه يخلق بيئة عمل أكثر كفاءة وأمانًا.

حزام النقل عالي الحرارة ليس متساوي الصنع. ليس كل نوع من أنواع حزام النقل عالي الحرارة يصلح لجميع الأغراض. لهذا السبب تحتاج إلى اختيار حزام نقل عالي الحرارة المناسب لاحتياجاتك. يمكنك اختيار النوع المناسب لاحتياجاتك من شركة شاندونغ شيانغتونغ روبير science. لديك مجموعة متنوعة من الخيارات المتاحة، والخبراء هناك سيساعدونك على العثور على الخيار الأنسب لك.