Ever wonder how large blocks of wood are chopped down into smaller pieces we use for furniture and other things in our daily life? This important task is done by a special machine; sawmill with the help of conveyor belt. The conveyor belt is a long, moving strip that moves logs and wood pieces throughout the sawmill. It does the log moving, cutting logs into smaller pieces and also delivering these to other machines. The conveyor belt contributes greatly to the wood industry and helps keep everything running like clockwork.

Just picture if the employees needed to deliver them ONEbyONE..279 Furthermore: logs and huge pieces of wood manually instead using are requested connect you (in order!) They would struggle and suffer very hard to do so. They would quickly fatigue, and furniture (along with other items) would be incredibly slow to produce. This is why the sawmill conveyor belts are necessary. They can easily and quickly help transport the wood from one location to another making it easier for you to work. For people employed in the sawmill, this will save time and money when the process is accelerated.

Turning a log into usable wood would take an immense amount of time without conveyor belts. But since sawmills can work much, much faster and better using conveyor technology. Sawmills use a variety of types and styles when it comes to conveyor belts, but they all help companies increase their production output with greater efficiencies. For instance, on some of the conveyor belts you will cut directly to his edger while other pieces of wood are taken by others machines. Some even have conveyor belts built in to sort the wood and stack it cleanly. Every different kind of conveyor belt that the sawmill uses has its own function which keeps everything running well.

The conveyor belt in a sawmill is more important otherwise to keep everything going. It is sort of the soul to the operation Workers used the conveyor belt to know what tasks asked for them. When the Conveyor Belt Is Working Properly, Everyone Can Work Faster And More Efficiently However, if the belt fails or stops moving, the entire line then comes to a halt forcing production to cease. This hinders progress and reduces their ability to deliver on time. Therefore, maintaining the proper functioning of a conveyor belt is critical.

For the wood industry, actually conveyor belt is kind of a back bone for all process. It is the thing that keeps everything in motion and brings order to the entire production process. The use of conveyor belts makes the work at the sawmill more efficient as it would take significantly longer for workers to do their jobs without them. Over the years, conveyor technology has become more efficient and new designs are making advancements in order to make that process easier.

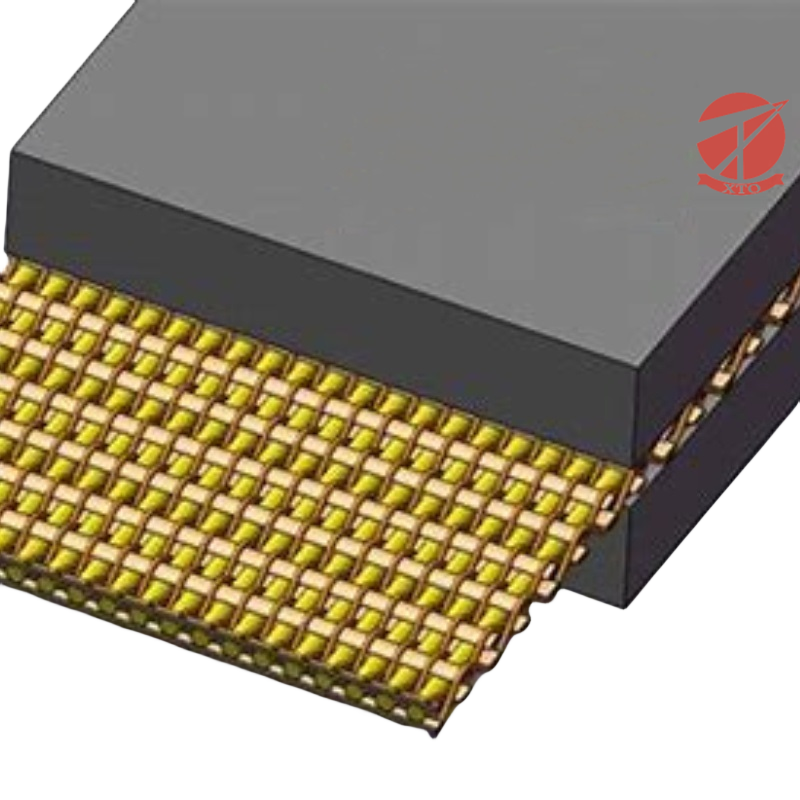

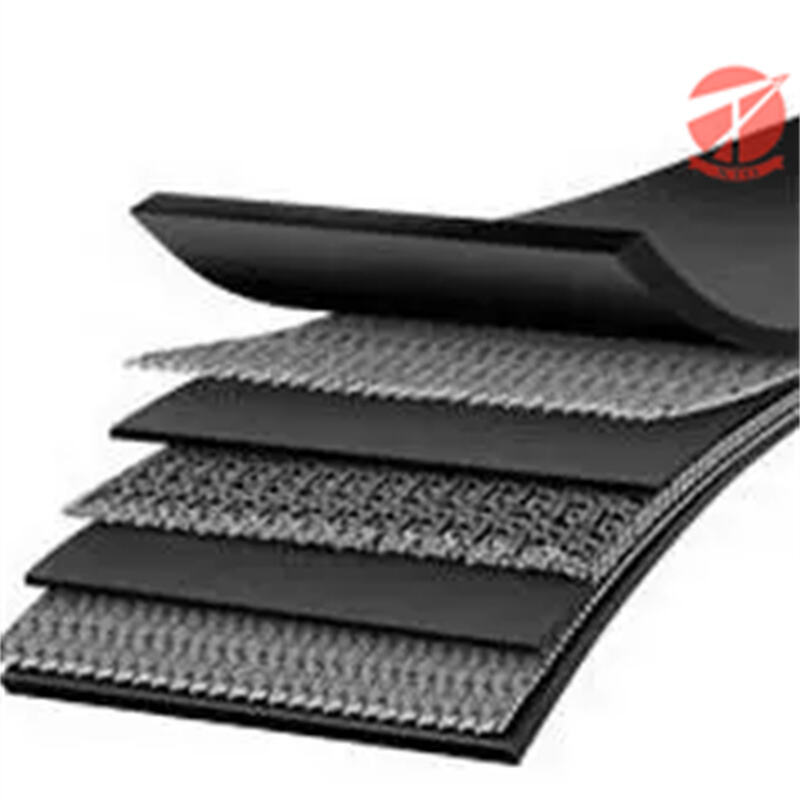

The range of products includes sawmill conveyor belt made of steel cord multi-ply textile belt the solid conveyor belt, and pipe belt, sidewall belt with patterned belts, lifting belt and the aramid conveyor belt. The annual production capacity of design is 29 million square meters of conveyor belts. Among these: We have 11 solid woven conveyor belt production lines, four multi-ply production lines, and 7 steel cord conveyor belt production lines. The longest conveyor belt made of steel vulcanization machine in Asia.

The company has advanced production equipment, a professional management team, and first-class technology to ensure that the firm has become a renowned competitive enterprise The PVG conveyor belt is the sawmill conveyor belt of the market in China. We are vice chairman of China's conveyor-belt field, and is one of its leading makers. The company has been awarded awards such as "China Quality Brand" and "The Most Influential Brand in the Field of Conveyor Belts in China" and many more.

ISO9001, ISO14001, and ISO45001 are sawmill conveyor belt standards that we have been able to pass. And our products have repeatedly passed the quality testing conducted by renowned organizations like RWE, TUV, BV, MSHA and MASC.

We have a sawmill conveyor belt RD team with experts who are setting national standards. We have also obtained 32 national utility model patents such as "multi-ply conveyor belt made of textile" and has declared 3 invention patents as well as 11 utility model patents such as ultra-wear-resistant conveyor belts and has collaborated with a number of universities, which shows the company's leadership position in the field of rubber technology. We also have a large and highly skilled after-service department made up of 32 individuals.