Rubber itself is a unique material and it comes in applications used for creating multiple items. Tires on cars, hoses to water plants with, gloves which protect our hands and conveyor belts bring material from one place to another. Conveyor belts play a major role in escalating the performance of industrial operations various industries. England has a lot of companies which make rubber especially for conveyor belts and that is why the quality maintained by them ids really high.

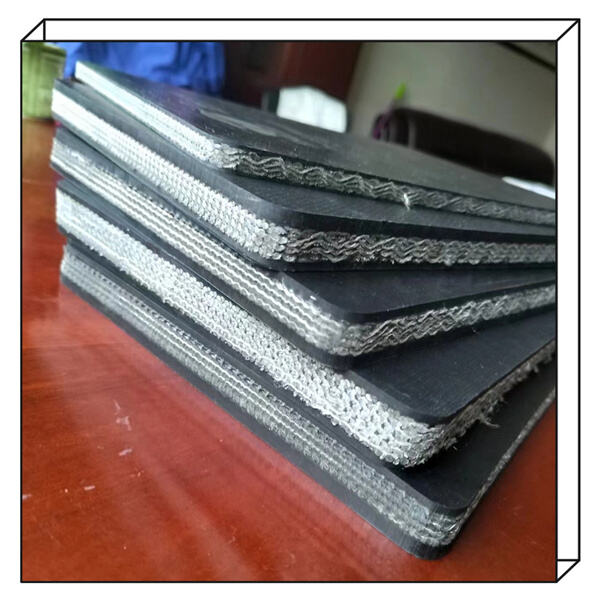

The first most important functions of the conveyor belt need to do with power and durability. This is accompanied by heavy-duty rubber which allows the weight and pressure of items being constantly moved on it. These conveyor belts are produced in England and the rubber they use is of high quality, making sure that it takes much longer until these materials eventually break or tear down completely.

Rubber for conveyor belts, they are no doubt a major output in engineering.However, based on the latest info, we also have some of the best rubber companies specialized solely in this part is found right here under our nose! A diverse mix of fresh graduate… I reckon these companies are known for their solid and consistent rubber products. Also, in making conveyor belts that are indispensable for transporting a variety of goods makes use of top grade material. But it was not the end of innovations for this kind as technology too started to keep moving further and these companies also spent on new age technological equipment that helped them manufacture better conveyor belts. This is how they can build strong belts and have them function correctly, suffice to say over time these turned into the most reliable solution for businesses.

The strength of the rubber is also higher; there are any number of different types dacron belts that can be specifically designed to suit a particular need. It also means that it can be produced in as many sizes or shapes for fit to the needs. There are a lot of conveyor belts that you can purchase in England. Packaging: There are several types of conveyor belt systems for packaging which includes flat belts cranial adapters, pack off station and modular plastic wide belts. While every type of conveyor belt serves a different purpose, they have been designed to meet the needs of varying industry types.

You also need to make sure about being friendly with the environment while producing conveyor belt rubber. The good news is that in England, many companies are making such efforts to use ecological raw substances for production. They have an unwavering commitment to making sure the rubber they produce can also be recycled with ease. This prevents the waste being generated, a small step to protect environment.

These companies use eco-friendly materials, and also follow energy-saving procedures in their production. This is them taking steps to reduce their carbon footprint, but not at the cost of producing cheap conveyor belts. Never sacrificing the quality of your products, these environmentally friendly processes are enough to develop robust conveyor belts that provide customers a good option and benefit not only them but also helpers like nature.

Choosing a supplier for rubber conveyor belts is not at all an easy task as trust, and reliability are key factors to consider. There is, of course a great deal of reputable suppliers in England They also partner with some of the industry-leading manufacturers across the nation to deliver top-notch items for their loyal customers. The other thing to keep in mind of these suppliers is that they take excellent care of their customers, which means they will go out of their way for you and make sure your experience with them was a good one