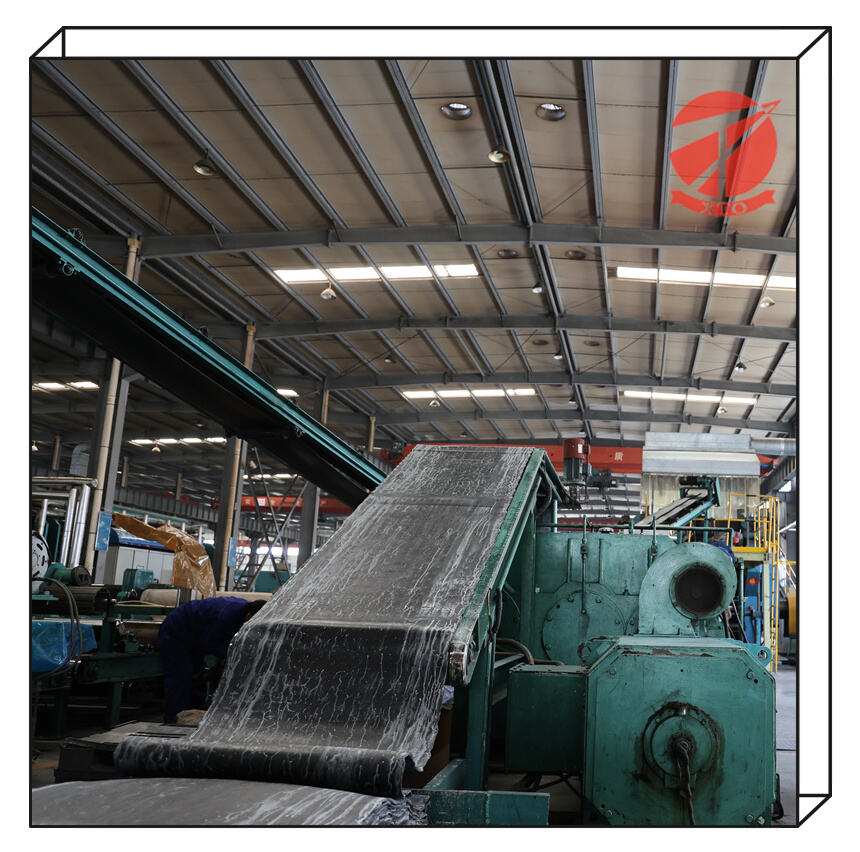

Rubber conveyor belts are very common in many factories or manufacturing plants. They are an integral part of the transportation processes necessary for production lines, as they facilitate movement from point A to point B. Conveyor belts are important to factories otherwise it would take longer and be more difficult to do many tasks without it. So, without further ado, lets have a closer look at 3 ply rubber conveyor belts and discover how they allow factories to become more effective and efficient.

Introduced the rubber bolide conveyor, a productidal ideal in factories and manufacturing plants. Prior to the invention of these belts, workers had no choice but to transport materials manually; a time-consuming and tiresome task that proved quite difficult. Fast forward to today, we have rubber conveyor belts which enable almost seamless transportation of materials without manual movement and these also allows workers to cater on other areas.

A 4 ply rubber conveyor belt is a collection of components that work together. The first of these is the belt itself, which consists of multiple layers of durable rubber. It is a durable substance that will not crack under weight. After that is the set of pulleys on either end of the belt. The pulleys guide the belt about, and maintain it centered. Lastly, there are the motors that operate the conveyor belt which assure it works continuously and effectively.

Rubber conveyor belts offer several advantages for manufacturing plants. And one of the biggest benefits is that they make workers more efficient. By conveying materials at high speed and with less friction between the conveyor system and worker, much time and effort are saved. It can increase the production speed hence factories can produce greater quantity of goods within less time, which is a critical factor of meeting customers demand.

Yet another thing to love about rubber conveyor belts, is the cost-efficiency it offers. Even though the conveyor belt requires an initial investment to be purchased, it eventually pays for itself in the long run. This is because with the option of utilizing a conveyor belt, it generally requires less manual supervision (which can be costly). Furthermore,they are extremely robust and available to the last longer throughout decades this investment provides great solutions for every business owner.

Just a wise business decision to invest in a rubber conveyor belt. As discussed above, these conveyor belts are a great way to boost productivity and are cost-effective in the long run. Also, they can enhance worker safety in the factory. If conveyor belts are not available, workers may be required to lift heavy materials and transport them separately, which is one of the causes of their injury. However, with conveyor belts, workers do not have to be at risk as they can move the materials in a safe manner.

Rubber conveyor belts are commonly used in mines areas for carrying heavy materials such as coal, stones etc. Because moving these bulky goods by hand can be quite hard and unsafe for employees, this is especially important. Rubber conveyor belts are equally important in the food industry too. These conveyor belts assist in transferring products in production lines and are very easy to clean as they are made of safe, food-grade materials. They ensure the cleanliness of food manufacturing, so they are safe to use as well suitable for food production.