And so, a conveyor belt is sort of like an extended moving sidewalk for the task to be shifted from one area to another. Think of when you step on an airport moving walkway and it helps take the work out or covering distance from one end to another. Conveyor belts are a crucial part of many businesses as they facilitate quick, efficient transportation. This allows customers to order products within days. However, just like how a large number of people can wear down the sidewalk over time so too when it's 18 wheels on multiple times throughout the day and night that run back-to-back runs across conveyor belts left to quite literally thousands or even millions of now in some cases registered miles either roundtrips or otherwise- they do eventually reach points at which enough material has gone through them its shredded whole surface open where no longer able function any longer up. This is where the ripstop conveyor belt comes in!

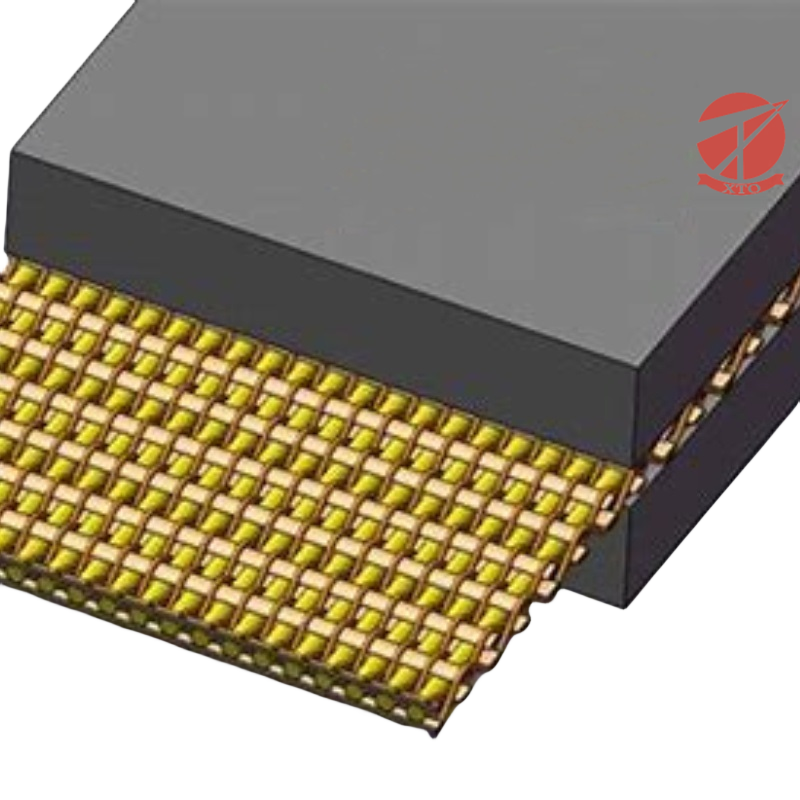

Special types of conveyor belts, being very robust and durable; for example like ripstop. They use advanced technology to make sure that rips and tears in the upholstery or fabric do not occur. It is like a magic cape that prevents damage from happening. In the event a tear does occur, this belt will prevent it from becoming any larger. The repair of its belts is really important as even though the belt gets a bit damaged, it will still manage to keep on working. For businesses, it is important that operations do not come to a crashing halt.

If a conveyor belt fails, it can put the stops on an entire operation. This may mean products need to be shipped a different way or will take longer to arrive at the final location. This can waste a lot of time and money, that nobody wants! So breaking is much less likely with a RIPSTOP CONVEYOR BELT. They are made cheaply and most likely will not handle the wear and tear that these belts do. This means that your business can operate like as usual regardless of the adversities.

Ripstop tech is kinda dope because it increases the efficacy of drive belts in a lot of ways. Initially, it helps to protect the belt itself and ensures that it requires fewer repairs or replacements over time. It saves a ton of money and time, which is crucial in any business. Ripstop belts are also capable of carrying heavier product loads compared to standard conveyor belts. This enables your business to pace additional products at a time which eventually accelerates the ability of industrial automation machines. Being able to move more products at once and on time helps keep customers satisfied as well.

Ripstop Conveyor Belts are widely used for heavy jobs. Ripstop is incredibly strong and hard to tear, therefore even if they get wet our dry sacks have the same properties as ripstop fabrics. A conveyor belt can experience a lot of strain when it has to bear heavy weights, and if the quality of the belt is not good then chances are higher that it will get snapped or broken easily. Ripstop belts, on the contrary are made for such pressure and do not break down. They also provide protection against rips and tears, meaning that businesses won't experience expensive repairs as frequently. Which is less to worry about and focus more on getting the job right!

The company has modern production equipment, a ripstop conveyor belt, and top technology so that the company has developed into a formidable competitive advantage for the business The PVG conveyer belt has most of the marketplace in China. We are vice-chairman of China's conveyor belt field and are among its top makers. The company has won honors such as "China Quality Brand" and "The Most Influential Brand in the Field of Conveyor Belt in China" and many more.

ISO9001, ISO14001 and ISO45001 are the three rigorous standards that we have been able to pass. Our products have also ripstop conveyor belt successfully passed the quality tests conducted by renowned organizations such as RWE, TUV, BV, MSHA and MASC.

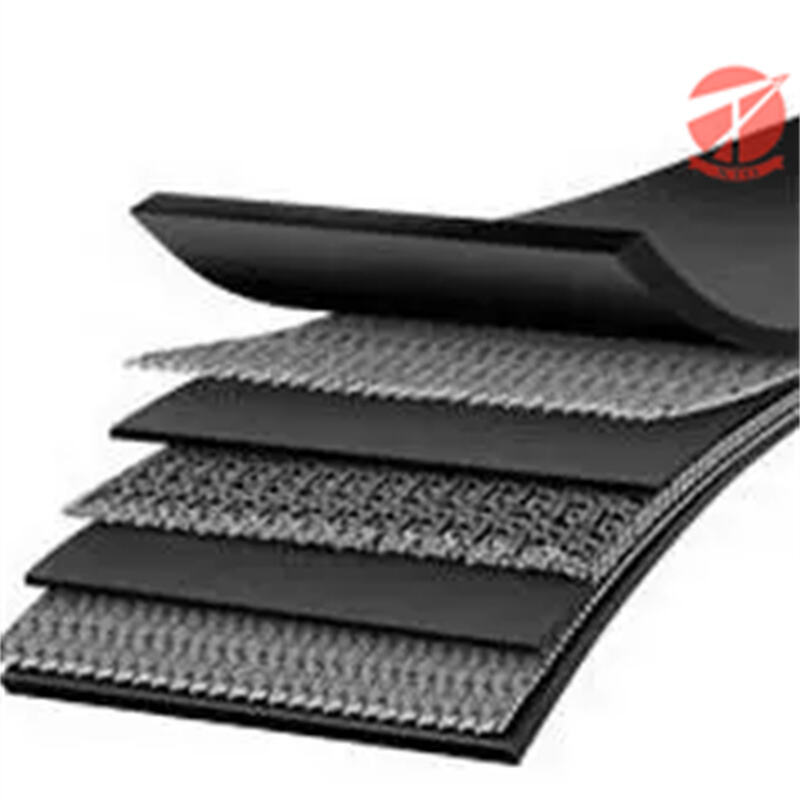

The range of products includes conveyor belts with steel cords as well as multi-ply fabric belts. the ripstop conveyor belt as well as sidewall belts, pipe belts and patterned belt, as well as lifting belt, and armid conveyor belt. The annual production capacity for design of 29 million square meters of conveyor belts. Among them, we have 11 solid woven conveyor belt producing lines. We also have four multi-ply fabric belt manufacturing lines, and seven conveyor belts made of steel lines. The longest conveyor belt of steel is vulcanization machines in Asia.

We have a skilled RD team with experts who are creating national standards. We have 32 patents for national utility models including the "multi-ply fabric conveyor belt", and declared ripstop conveyor belt and 11 utility model Patents, such as an ultra-wear resistant conveyor belt. Our company has worked with various universities to show its leadership position in rubber technology. We also have an extensive and highly skilled after-service department made up of 32 people.