In the production of energy, so that we can open up a lamp in our homes or simply at work - power plants consume mountains (! This process is very rapid in the case of materials such as coal and biomass, which must be moved a great distance. This is where using conveyor belts can be really helpful to simplify and automate this process.

Conveyor belt is a specialized machine to carry items from one point to another and other materials with effectively. They are employed in various industrial settings to the power plants etc. It is very crucial to have them as they are our carriers who bring the raw materials that we need for us where energy is produced.

Belts Speed Power Plants Along Materials have been logistically easier to move ever since power plants adapted conveyer belt technology for the movement of goods. Typically, greater efficiency translates into less downtime - or essentially time when a plant is not producing electricity. Less downtime, more energy production!

A conveyor can move a large volume of material at once; these designs work well for power plants as they typically need significant quantities of feedstock to operate continuously. On the other hand: things can be made more flexible again - even with standalone machines on roller conveyors in older plants, because no merging systems are needed which have been accumulated wisdom for decades. First, this makes them capable of being constructed to fit different weight and sizes allowing for the whole thing slide like that.

Also, conveyor belts very low maintainence so that is another good thing about them. That is also one of the reasons why so many power plant owner want to get hands on it. These machines require no downtime, which reduces both cost and time for power plants to have their energy levels focused on the creation of more energy.

Power plants are a hectic place and so any tool that can be used to finish these job is useful, less time consumed by the plant would naturally means no hampering of restorative or operations power output. Material handling has become easy only through the use of conveyor belts: A good number if material is being transferred from one point to another by simple movements and using a few seconds.

Sixty years later, new technologies for moving these materials around more quickly and efficiently have been invented. It also allows the matter that is in production transport to be easily filled, resulting a better flow and control of materials and an increase on overall plant energy creation. I mean that is another way of saying the plant produces more energy with lower costs and on top it meets a pipeless process.

We have a power plant conveyor belt RD team with experts who are setting national standards. We have also obtained 32 national utility model patents such as "multi-ply conveyor belt made of textile" and has declared 3 invention patents as well as 11 utility model patents such as ultra-wear-resistant conveyor belts and has collaborated with a number of universities, which shows the company's leadership position in the field of rubber technology. We also have a large and highly skilled after-service department made up of 32 individuals.

The company boasts modern production equipment, professional management team, and top technology, so that the company has developed into a formidable competitive ability of the enterprise and the PVG conveyer belt holds the highest percentage of the power plant conveyor belt in China. We are vice-chairman in China's conveyor belt market and also one of the leading makers. The company was awarded the honor of "China Quality brand" and "The most important brand in the area of conveyor belt in China", etc.

power plant conveyor belt, ISO14001 and ISO45001 are the three strict standards we have successfully completed. Our products have also repeatedly passed the quality testing conducted by renowned companies like RWE, TUV, BV, MSHA and MASC.

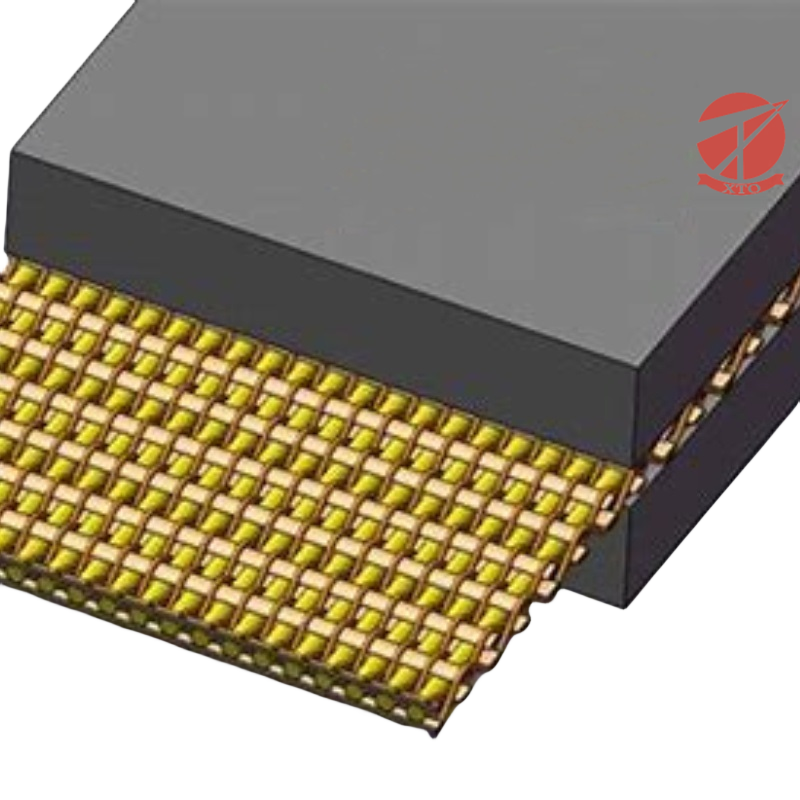

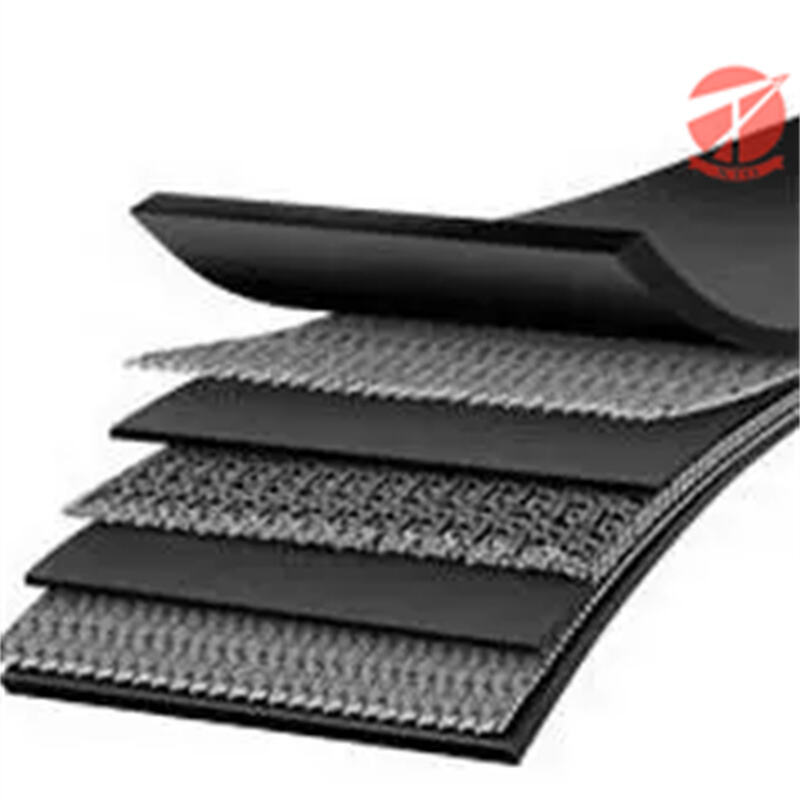

Our range of products includes steel cord conveyor multi-ply fabric belts solid weave belts, power plant conveyor belt sideswalls, patterned lifting, and Armid belts. We have 11 lines for solid woven belts, 4 lines for multi-ply fabrics, as well as seven lines for steel cord belts. It also has the longest steel conveyor belt cold vulcanization line in Asia.