One such type of fixture is plastic conveyor belt This kind of belts are most commonly needed as it offer a help in transporting any weight from one spot to another. These belts are used in many places, for example factories and warehouses. First and most important, they may be made out of long lasting plastic material supplies that leads to numerous benefits more than various other types regarding belts which are manufactured through several materialsstreams.

Plastic conveyor belts make for more durable conveyors that hardly need any maintenance. This just implies organizations do not need to count the pennies while overhauling them from time to time. Their durability will save business costs in the long run. These belts are also easy to clean. Because they are plastic, it is non-absorbent so there will be no filth or gunk buildup. Also suitable for tidy rooms. So, belts are that light it is simple to move your plain as well and also carries inany place.

Industry Moving items inside factory and warehouse 24/7 Box, part & goods industires...must be fast and work on a global scale. The benefit of using plastic conveyor belts for these products is that companies do not need to worry about transporting them. They ensure everything arrives exactly where it needs to be, right on time - so the workflow goes as scheduled. The belt moves the items for them, allowing workers to work by moving and doing other tasks.

Sometimes, companies need things to happen very fast - steroids for production at scale. Like: its potty important to get the parts in and out when a plant manufacturer manufactures cars or electronics. Plastic conveyor belts are ideal for this. Balance is especially important in a full scale production process, and getting everything to move fast (and with easy flow - it did!) requires being deliberately thoughtful. For everything to remain on course, and the production cycle continues without any kind of obstacle.

Particularly if something is being transferred a great many times, like in one of those places where that sort of thing gets moved frequently enough and the building has lots working there. Plastic conveyor belt plays an important role in terms of safetycribnotes They are also lightweight and can be moved out of the way should a spill or something fall in order to prevent accidents. In addition, they are easy to clean making them ideal for preventing the spread of germ and bacteria. In some places, such as in food production where it is particularly critical that those areas remain very clean.

A lot of these jobs and industries are also heavily dependent on plastic conveyor belts (if you've ever seen food being produced or cars manufactured, this is what those iconic machines typically run on). These belts are widely used in the food industry bacuse of this property that they can be washed and germs or any other weird stuff dont stick to them. Furthermore, they can be employed to transport food without breaking or squishing sensitive foods. These belts are commonly utilized to move large parts from one station to the next, down a production line in automotive manufacturing. This type of robots can sort all kinds, from large boxes to small parts in warehouses and are created specifically for organizing things.

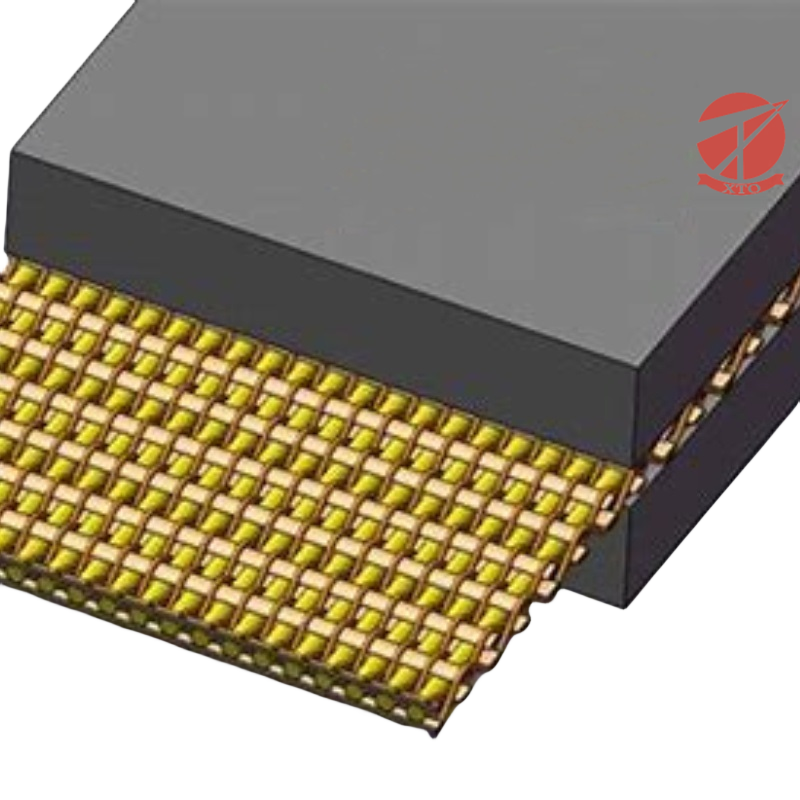

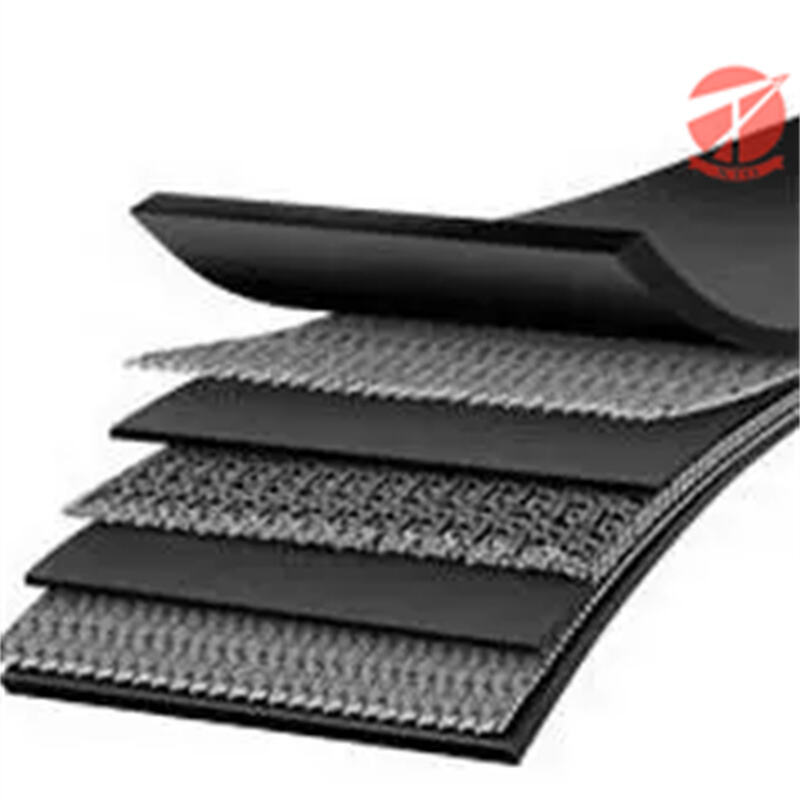

The range of products includes plastic conveyor belt made of steel cord multi-ply textile belt the solid conveyor belt, and pipe belt, sidewall belt with patterned belts, lifting belt and the aramid conveyor belt. The annual production capacity of design is 29 million square meters of conveyor belts. Among these: We have 11 solid woven conveyor belt production lines, four multi-ply production lines, and 7 steel cord conveyor belt production lines. The longest conveyor belt made of steel vulcanization machine in Asia.

ISO9001, ISO14001 and ISO45001 are rigorous standards that we have achieved. Our products have also repeatedly been tested for quality by plastic conveyor belt companies like RWE, TUV, BV, MSHA and MASC.

Our RD team is comprised of experts who are responsible for setting national standards. We have plastic conveyor belt national utility models patents for example, the "multi-ply fabric conveyor belt" and have declared three invention patents and 11 utility model Patents, such as an ultra-wear-resistant conveyor belt. The company has also joined forces with several universities to show its leadership position in rubber technology. We also have a large and reliable after-service staff made up of 32 people.

The plastic conveyor belt is equipped with the latest production equipment, a highly skilled management team, as well as top technology. The company has grown into a strong competitive ability of the enterprise and the PVG conveyer belt has the largest share of the market in China. We are vice chairman of China's conveyor belt industry, and are among its top makers. Our company has received awards such as "China Quality Brand" and "The Most Important Brand in the World of Conveyor Belt in China" as well as other awards.