Many different jobs and industries benefit from anti tear steel cord conveyor belts. They are created from a particular type of tough rubber known as nitrile. It is what makes the belts so sturdy as to not break or get damaged easily over time. There are several fantastic advantages of utilizing nitrile conveyor belts which is why they are widely used for all sorts of task. In this write-up, we discuss the benefits associated with using nitrile conveyor belts for different jobs and how they help to make operations more efficient and eco-friendly.

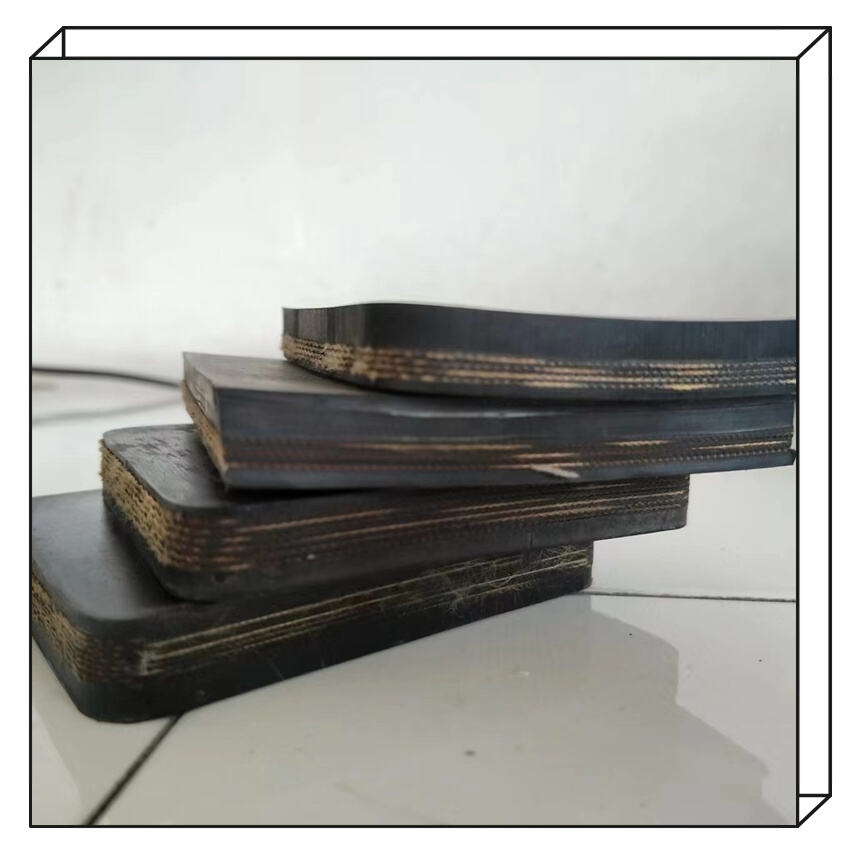

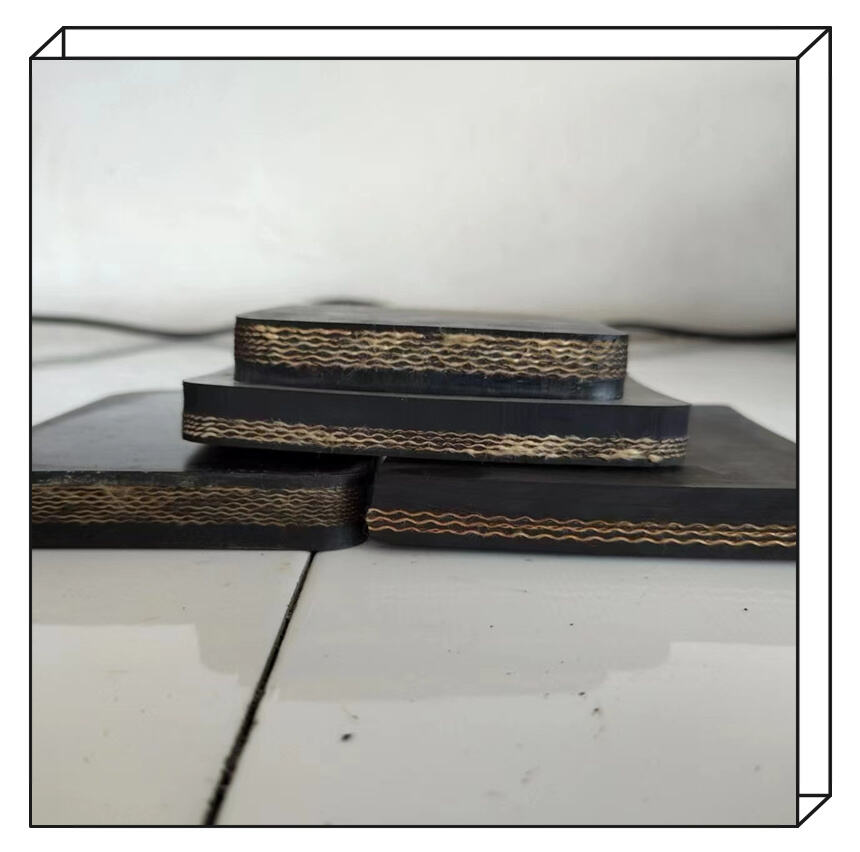

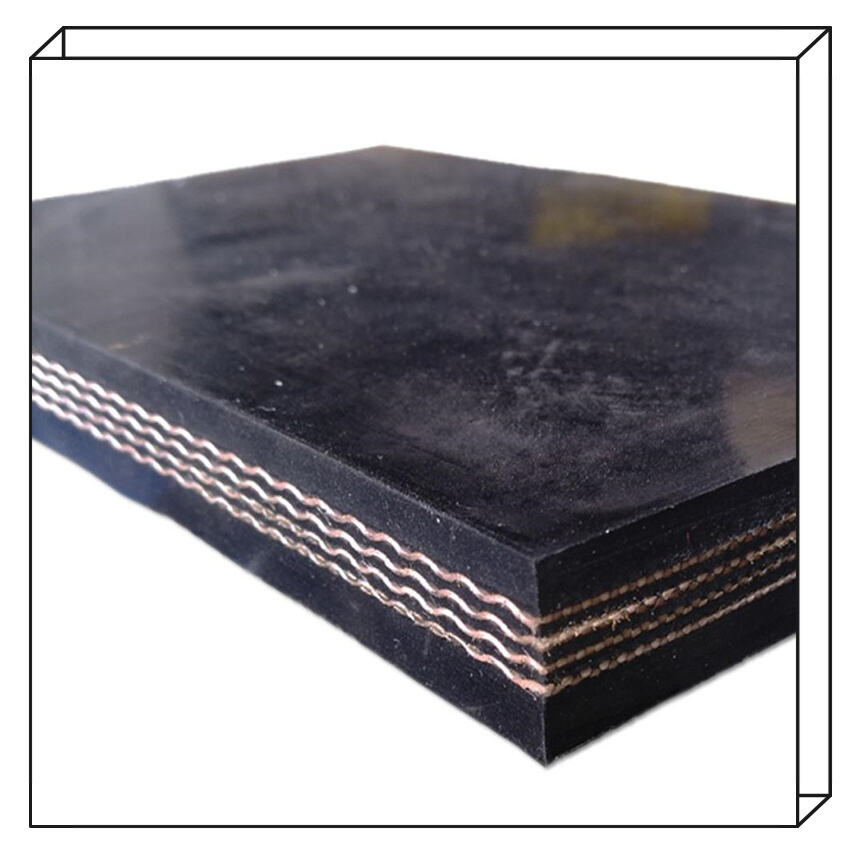

This makes the nitrile conveyor belt, and why they are a great fit over other types of these belts. For one, they are extremely sturdy and resilient. It also allows them to carry extreme weights before being damaged, which is ideal for industries with large cargo items. These belts are also resistant to oil, grease and chemicals. They are ideal in applications where workers work with oils or harsh chemicals. Additionally, nitrile conveyor belts are purposefully used in multiple temperature levels. Also, they can live in both hot and cold environments; therefore are very flexible and perform well in different settings.

Nitrile conveyor belts can be used for a wide range of applications, including moving bulk material from one location to another. They can, for instance, be used in mining, agriculture, construction and a whole lot of other industries. These belts domain especially useful in mining, where heavy rocks and minerals have to be transferred. They can be used in agriculture for moving grains and other products. Nitrile conveyor belts are particularly well-suited for oil, grease and chemical-intensive applications because of its high chemical resistance. They are also frequently used in factories, aiding the transfer of goods along production lines to ensure seamless and efficient operations.

Nitrile conveyor belts do wonders in speeding-up operations in a wide range of industries as well. They are very strong and able to carry heavy loads without any breakdown. That means it quickly moves materials, which saves the companies using them time and money. Nitrile not only allows for the use of such conveyor belts, but also automates processes as well. Automation allows the use of machines to do tasks that are typically done by large numbers of workers. This will simplifying the work and requires lesser workers to get something done which means reduced labor cost and more focus on important tasks for workers.

Nitrile is very well suited to the heaviest of tasks and hence is used in industries needing rue cleaning ability. They have enough strength to lift heavy weights without difficulty. Additionally, they provide resistance to oil, grease and chemicals that means they can function in areas in which other belts fail. These belts can also resist high temperature which makes them suitable for job where there is excess heat. Thus, they serve as an excellent option for industries requiring high-quality conveyor belts. One example: They are frequently used in mining and construction, where they can transport large volumes of material quickly and safely over long distances.

Nitrile conveyor belts can also be an eco-friendly option. Some of the prominent manufacturers of assembly line conveyor systemss are Shandong Xiangtong Rubber Science. They emphasize on sustainable materials. So their belts are not just heavy-duty, they also cut down on waste and save energy. The environment is also positively affected through the promotion of eco-friendly materials to use as they cause less pollution and require a significant amount of natural resources too. Such is a really big step that leads towards the sustainability for all of us.