Their food, your car if you buy one from there I hope or some other appliances and things... do you wonder how the products got to your store? Or, have you ever wondered how toys and other products are made in factories? One of the essential phases of the process is - moving materials. This is simply transporting items from one location to another. This is done by a machine called as conveyor belt. It is like a huge highway bringing stuff where they need to be.

A belt conveyor is normally a long strip or gird that moves in rounds, similar to a loop. Objects that must be moved are put on this band. The conveyor belt then mobilizes and brings these articles to their necessary positions. It may be some other section of a manufacturing facility where they manufactured or dispatched, it can also the end in which them could make test it out area for food market goods and their genuinely bagged up are prepared to take building.

They all move fast (industrial conveyor belts are very Livid-y) This enables factories to create things more quickly, and it also means you can check out at a grocery store quicker as well. If you have ever been to a package-while-you-wait kind of center then you know, they do the impossible without breaking a sweat. Picture no conveyor belts and all those boxes moved by human hands,,, it is backbreaking work; that its why there are fewer of them around than travelers aboard Noah's Ark.

A conveyor belt speeds up the process by shifting products between departments of a factory as they are being assembled. This Aşağı Maltepe depolama sistemleri makes the works easy for workers as they do not have to transport some of them by moving themselves physically. In addition, it keeps workers safe since they are not lifting heavy items which can lead to injuries.

Each factory is different, so keep in mind that there will be no 2 factories alike. The versatility of conveyor belts is one awesome advantage, as the lengths and features can be swapped out to suit differing requirements As a result of this the factory owner can find a conveyor belt that perfectly matches their individual tasks and production process.

Factories are also able to produce product in a more cost effective way by using the conveyor belt. The conveyor systems are designed to do one thing extremely well - move items - and it uses far less energy than moving things by hand. During the summer this means that factories can cool down without using extra electricity and in winter, they are able to recover energy for free cooling.

Conveyor belts impress in many factories and manufacturing processes It eases the movement of loads so, construction work can be completed faster. However, they are usually useful in many control usages as their physical properties can be modified to meet the pertinence of a dynamical system. This will save space and reduce labor costs as well because a conveyor system decreases waste.

The company boasts modern production equipment, professional management team, and top technology, so that the company has developed into a formidable competitive ability of the enterprise and the PVG conveyer belt holds the highest percentage of the material conveyor belt in China. We are vice-chairman in China's conveyor belt market and also one of the leading makers. The company was awarded the honor of "China Quality brand" and "The most important brand in the area of conveyor belt in China", etc.

material conveyor belt, ISO14001 and ISO45001 are the three strict standards we have successfully completed. Our products have also repeatedly passed the quality testing conducted by renowned companies like RWE, TUV, BV, MSHA and MASC.

Our RD team comprises experts who are responsible for setting standards for national use We have 32 national utility models patents for example the "multi-ply fabric conveyor belt" and declared 3 invention patents and 11 utility model patents for example like an ultra-wear resistant conveyor belt Our company has formed partnerships with universities to show its leadership position in rubber technology We also have an extensive and efficient after-service team made up of material conveyor belt

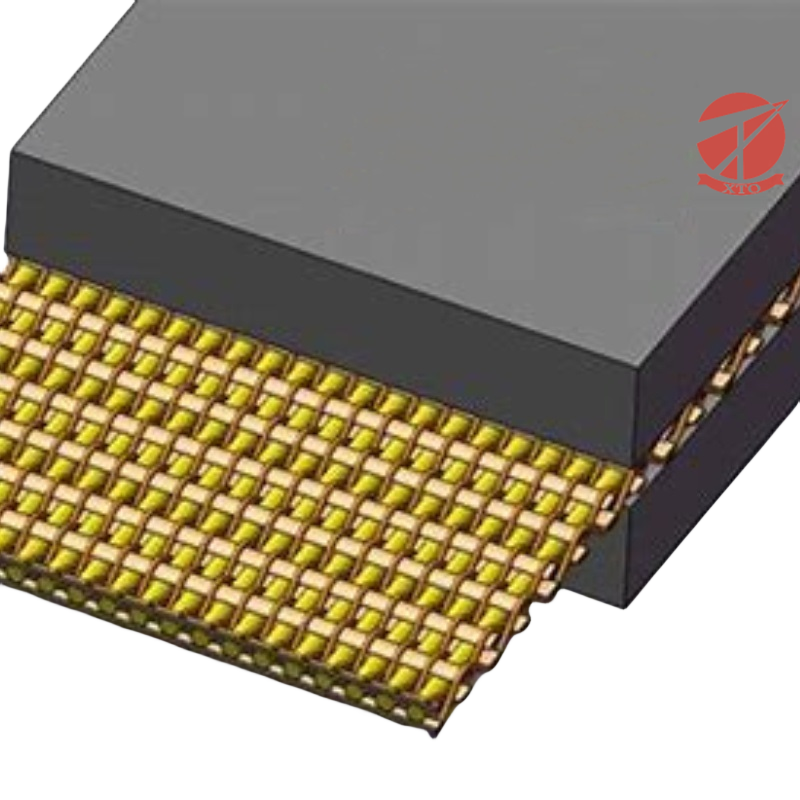

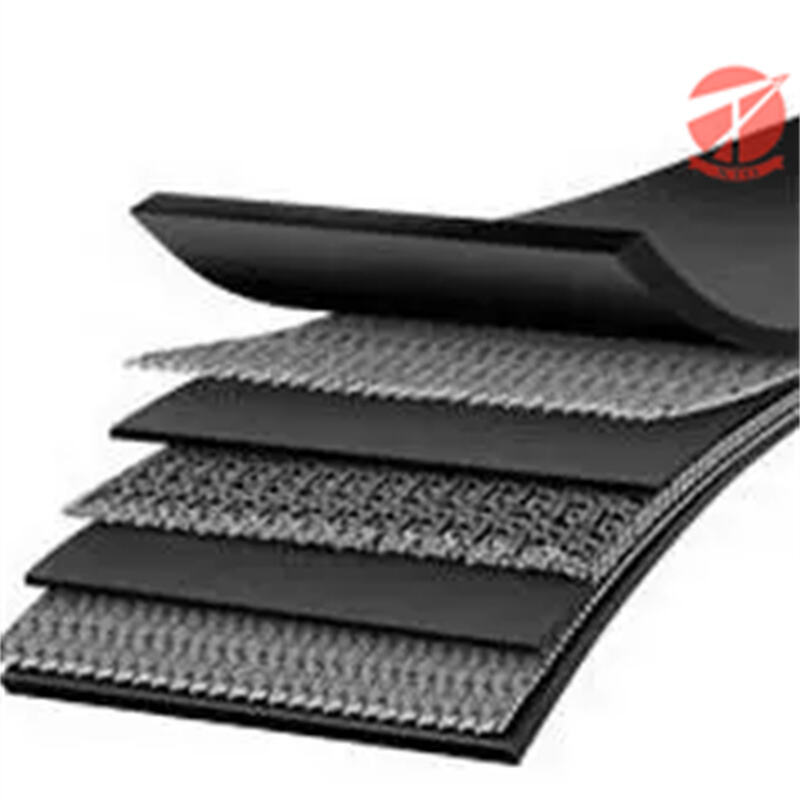

The material conveyor belt range covers steel cord conveyor belt as well as multi-ply fabric belts. the solid conveyor belt as well as sidewall belt, pipe belt, patterned belt, lifting belt, and an aramid conveyor belt. The annual design capacity of 29 million square meters of conveyor belts. Among them, we have 11 solid woven conveyor belt production lines, 4 multi-ply textile belt producing lines, and 7 conveyor belts made of steel lines. It also has the longest steel cold conveyor belt vulcanization equipment in Asia.