The conveyor belts are one of the special types of belts which help in moving things from their location to another. They might be in factories, warehouses or airports. Conveyor belts changed the way things were produced and greatly assisted in improving working standards for many companies which into complex engineered chain,replacement,turing roller drive,flat fruit conveyor belt,wire mesh tape. They are the essential as you move your items quickly and efficiently.

Factories were far slower before conveyor belts came to be. It took a lot of people to transfer materials and finished products from one location to the next. This inadequate method made the work very time consuming. As the mule cars of people moved more slowly, a machine could move things along at an even quicker rate. This allowed factories to manufacture faster without costing too much. Businesses became more successful, and as a result they could make more goods to sell.

Conveyor belts of today are more advanced and different from the original models built. Well, they are built using latest materials and techniques making it tough as well in terms of ride. Today, conveyor belts can transport the heaviest of industrial mining equipment and materials such as coal and asphalt. Additionally, they are built to handle a variety of temperatures ranging from very cold up to scorching hot. This is necessary to ensure that they are useful in many industries.

The good thing is that it can be customized with the modern conveyor belts to meet your specific requirement. To give an example, a food company could need belts that can resist spills and are easy to clean. It is crucial to maintain this in order for the food to be preserved and safe. Conversely, a firm in the business heavy equipment manufacturing could require robust belt that withstands huge and weighty components. These customizations enable businesses to work more efficiently.

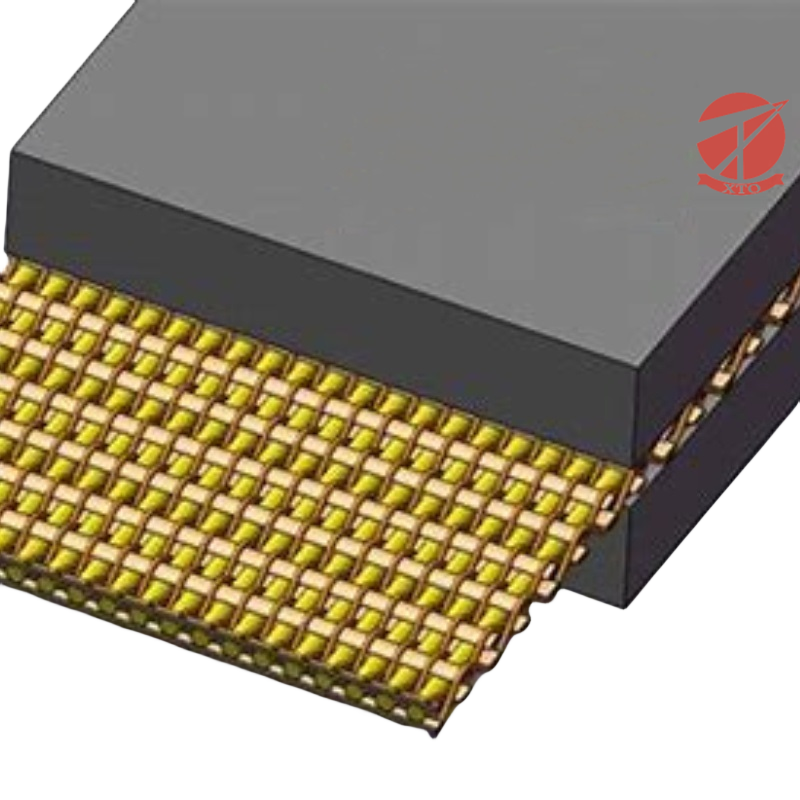

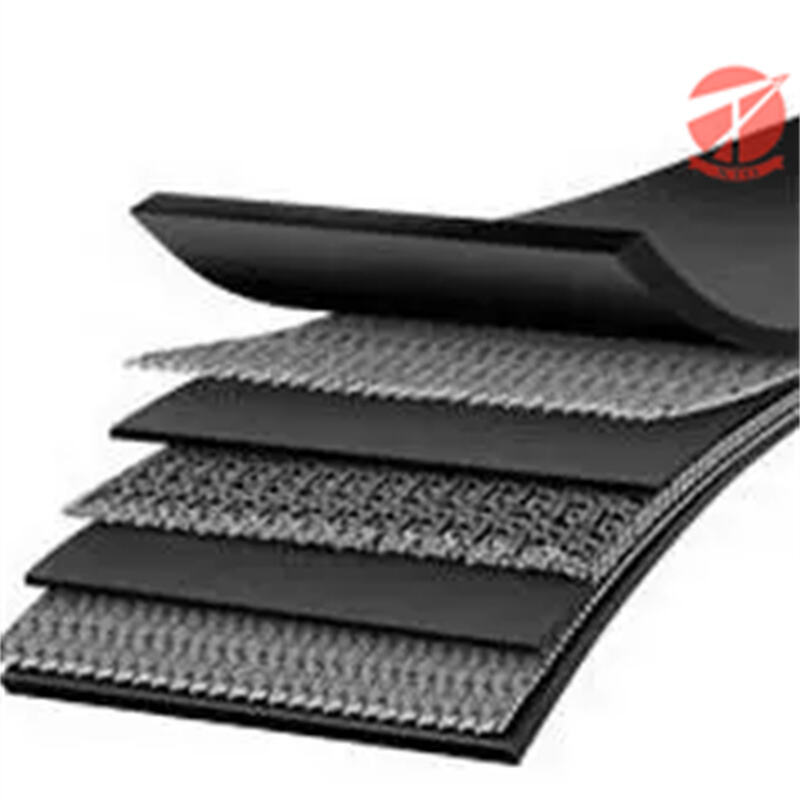

These belts can be made from a variety of materials such as rubber or plastic, but due to the high friction issue raised with each wear it is advisable that they are only used on non-metallic items. Rubber belts are the most universally used, and will do just fine in any number of scenarios. Metal belts are used in different industry areas like the automotive sector which requires a robust belt. Non-metallic belts are also used in clean environments such as food and pharmaceutical by running a plastic belt.

Different types of Conveyor Belt Design with Different Material Optibelt's Timing belts, for example are flat and are content with moving items straight across or up/dowhill whereas all of our V-belts meet the demands of >90% belt drives. Certain belts have particular designs so that you can carry your small or delicate stuffs without spoiling them. It is this versatility that makes conveyor belts useful in a variety of situations.

One thing that is for sure, conveyor belt technology will continue to evolve and improve. The process of moving things around has evolved so that there are newer ways based on new innovations and emerging trends that make the whole task an even more effective one. A promising trend is warehousing with robots (or bots, in industry parlance) that move goods, not people. This is how it ensures the safety of workers as well at a faster Process due to reduced risks.

The company is equipped with the latest production equipment, professional staff, and manufacturing conveyor belt, so that the company has grown into a strong competitive enterprise The PVG conveyer belt holds the highest percentage of the marketplace in China. We are the vice chairman of China's conveyor belt industry and one of the standard makers. The company was awarded the honor of "China Quality brand" as well as "The most significant brand in the world of conveyor belts in China", etc.

We have a manufacturing conveyor belt RD team with experts who are setting national standards. We have also obtained 32 national utility model patents such as "multi-ply conveyor belt made of textile" and has declared 3 invention patents as well as 11 utility model patents such as ultra-wear-resistant conveyor belts and has collaborated with a number of universities, which shows the company's leadership position in the field of rubber technology. We also have a large and highly skilled after-service department made up of 32 individuals.

The product line includes conveyor belts with manufacturing conveyor belt multi-ply textile belt solid woven conveyor belt, as well as sidewall belt, pipe belt and patterned belt, as well as lifting belt, and aramid conveyor belt. The annual production capacity of design is 29 million square meters of conveyor belts. Among these: We have 11 solid woven conveyor belt producing lines, we have 4 multi-ply textile belt producing lines, and seven steel cord conveyor belt producing lines. The longest conveyor belt made from steel vulcanization equipment in Asia.

We have manufacturing conveyor belt able to pass the strict requirements of ISO9001 and ISO14001 as well as ISO45001. Our products have been through quality tests carried out by respected organizations like RWE TUV BV MSHA MASC.