In factories and mines, conveyor belts are large moving walkways that assist in the movement of items from one place to another. Think of it as a very long, thin belt that wraps around and around to carry things like big rocks or dirt in tiny increments. Or groceries! Now, these conveyor belts have become so handy as waste no time and energy. Especially in mining, there is one special kind of conveyor belt called the iron ore conveyor. So let us delve into what this critical conveyor belt is and why it has proven to be so effective in the mining process.

A conveyor belt is a kind of heavy duty rubber rings that help in carrying and transporting things from one place to another. The long bands loop endlessly, fed by motors that drive the conveyors and everything on them. Around the world, they are heavily relied on for transporting items rapidly and fluidly in various plants factories mines. Even stuff as heavy as rocks with dirt, or your groceries in the line at a store! Those automations in turn save time for workers and generally ease the process.

Iron ore is a kind of rock that we use to make steel, and when you build things like cars or buildings, the machine needs steel (very much). Where Iron ore is located deep inside the earth and it has to be taken out using special machines so that people get minerals safely. Such machines include huge vehicles, drills as well as other devices required for mining. After the iron ore has been removed, it is transported to a processing plant. In the processing plant, several different types of machines are working to bring iron ore from poorly prepared state to a form where it can be used for steel manufacture or later straight products. The iron ore conveyor belt is a critical element in this process, as it helps transport the ore from one end to another.

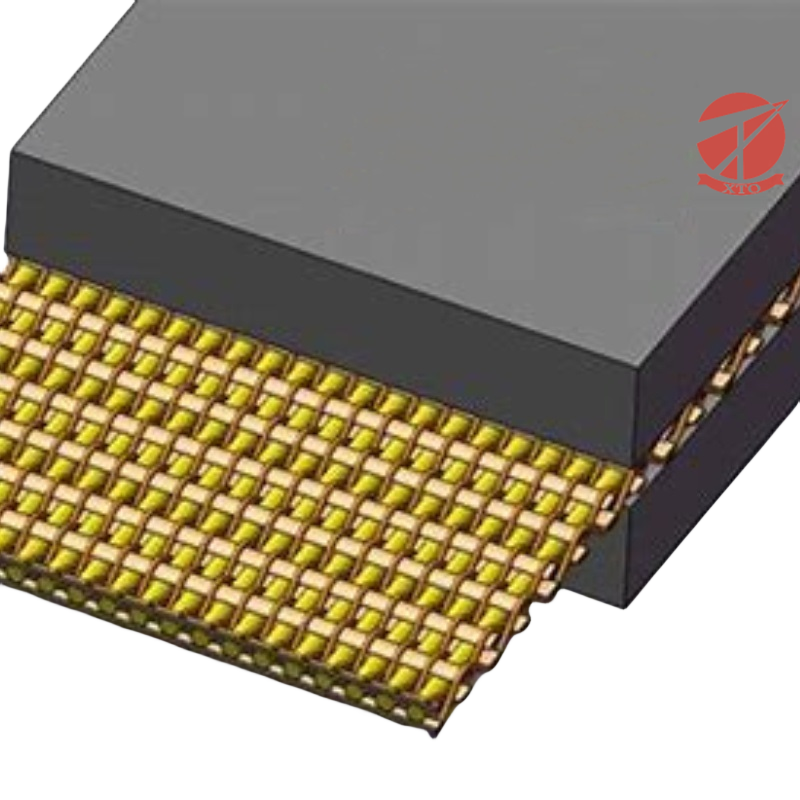

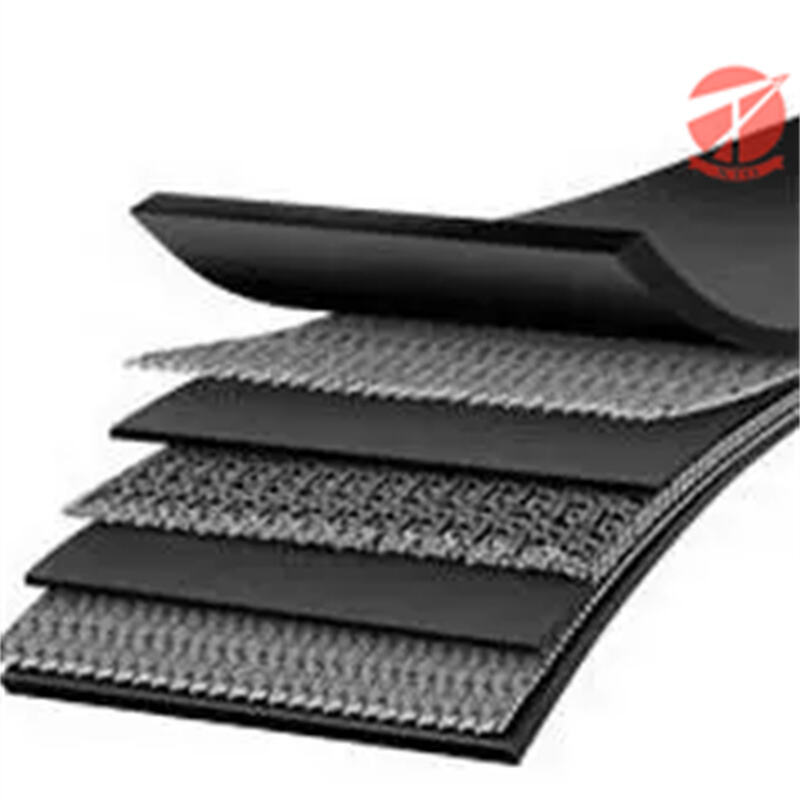

Iron-Ore-Conveyor-Belt_1 The iron ore conveyor belt is a special rubber layer with high mechanical strength and load-bearing capacity to transport materials. Using rubber, PVC, metal or fabric materials it can be customised to the requirements of the mining operation. This belt is usually large enough to carry massive amounts of iron ore, and one way conveyor belts are very efficient. Iron ore is dumped on to the stacker belt, which transports it moving forward over long distances before arriving at its final resting spot.

More efficient handling of materials on a conveyor belt in an iron ore mine. Workers no longer Must lug giant loads of heavy metals by hand ( wearing them out over time which can be reversing and takes more amount of labour ) At a faster pace, workers can also transport heavier amounts thanks to the conveyor belt This is crucial given mining needs to happen quickly and be profitable as someone else will do it elsewhere for cheaper.

Iron Ore Conveyor Belt For sale mining conveyors for south-africa where is the cheapist place to bu. These haul freight boundaries between extraction sites and processing plants so that they can be turned into useful items. Mining would be a much slower, and workers of that time period definitely did not have the union benefits we enjoy today which means they would potentially be working with back breaking labor along side having to move material themselves without conveyer belts This may result in production times being slowed, and costs increased. Simply put, the iron ore conveyor belt is one of those crucial elements that ensure mining operations run smoothly and efficiently.

Always with a high focus on the mining area is safety. The use of conveyor belts, such as Iron ore belt or even coveyor tape can reduce much more the risk to which human beings become exposed when put in contact with hard work. This means reducing the risk of danger in a mine where mining accidents and injuries are very frequent thanks to machines taking on certain tasks. It creates a much safer work environment for all.

Our RD team comprises experts who are responsible for setting standards for national use We have 32 national utility models patents for example the "multi-ply fabric conveyor belt" and declared 3 invention patents and 11 utility model patents for example like an ultra-wear resistant conveyor belt Our company has formed partnerships with universities to show its leadership position in rubber technology We also have an extensive and efficient after-service team made up of iron ore conveyor belt

The company iron ore conveyor belt modern production equipment, a professional management team, and top technology, so that the company has developed into a formidable competitive advantage for the business The PVG conveyor belt is the largest share of the marketplace in China. We are vice-chairman of China's conveyor belt industry, and is one of its leading makers. Our company has been awarded distinctions like "China Quality Brand" and "The Most influential Brand in the field of Conveyor Belt in China" as well as other awards.

The product range covers steel cord conveyor belt iron ore conveyor belt belt the solid conveyor belt, and sidewall belts, pipe belts with patterned belts, lifting belt, and an aramid conveyor belt. The annual production capacity of design of 29 million square meters of conveyor belts. Among these: We have 11 solid woven conveyor belt producing lines, we have 4 multi-ply textile belt producing lines, and 7 steel cord conveyor belt production lines. The longest conveyor belt made of steel vulcanization machine in Asia.

iron ore conveyor belt, ISO14001 and ISO45001 are the three strict standards we have successfully completed. Our products have also repeatedly passed the quality testing conducted by renowned companies like RWE, TUV, BV, MSHA and MASC.