Simply put, the High temp belts are unique instruments in making machines run on par with efficiency. These are high-performance belts made of durable material that can withstand extremely high temperatures and will not wear/ slip off from the machine parts they drive. They are employed in various task fields like manufacturing, checking resources, collecting plants through maturation as long production and being cost-effective.

High temp belts play a very vital role in making machines work. They assist in lessening friction, the rubbing that occurs between moving parts. Less friction means the machine experiences less wear and tear, allowing it to last many more years. They eliminate the heat generated within the machines, thus assisting to keep these cooling using such belts. When machines run hot, components can flex, deform and even snap, resulting in costly repairs that take time to resolve.

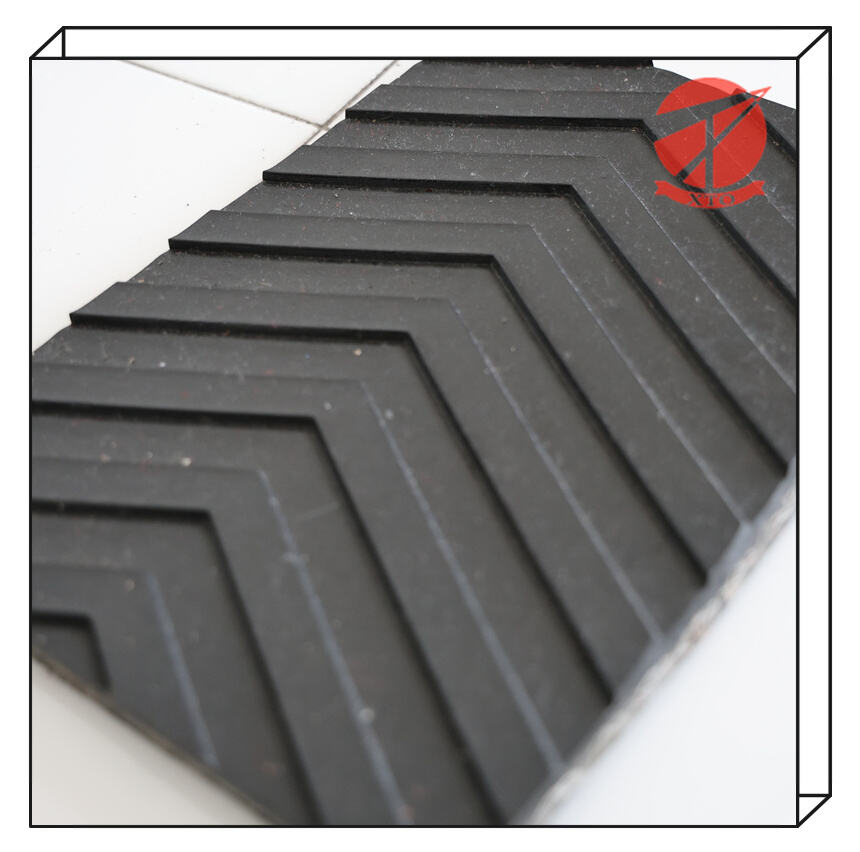

High temp belts are great because they show no problem with handling really hot temperatures. It works in places which are as hot as 200°C, making it ideal for jobs that involve hot working conditions such as factories, chemical processing plants, and steel mills. With the use of assembly line conveyor systems to control that heat companies are able to run their machines efficiently and not have down time costing them time as well as money when a machine breaks all of the sudden.

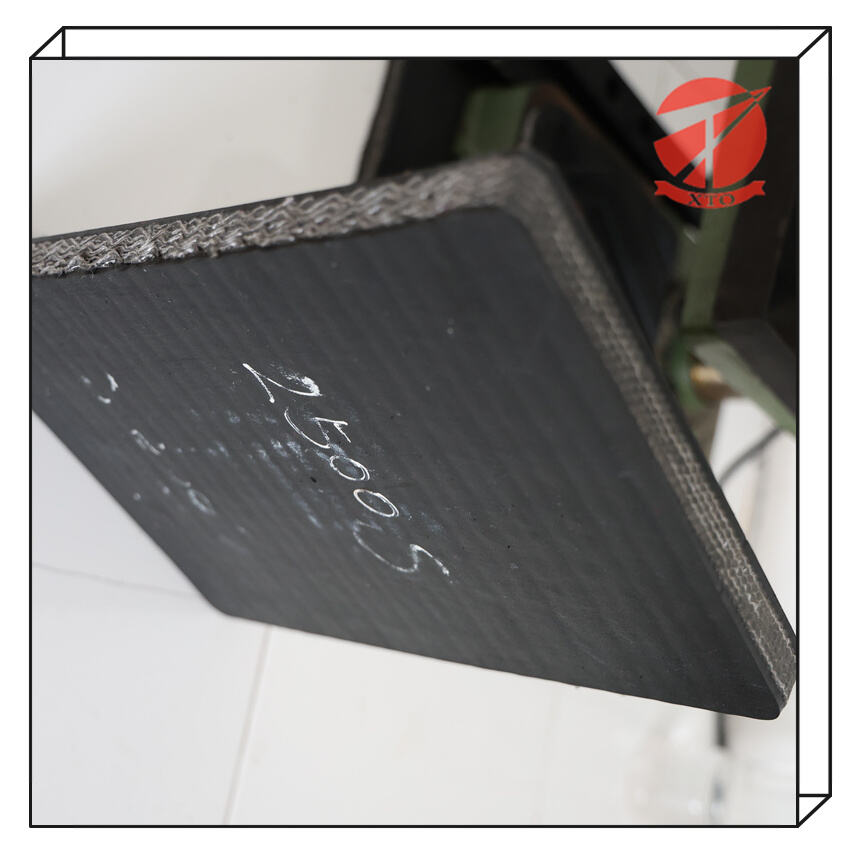

Not only are High temp belts useful, but they come very strong and high-quality. These belts do not wear and tear easily even under conditions of high temperature, harsh chemicals, and continuous operation. As a result, they're ideal for difficult tasks where machines tend to be pushed very hard. This means that high temp belts have an incredibly long lifespan and therefore save businesses money in the future by not requiring replacement for years.

Business can implement high temp belts to enhance its functionality at the fastest pace. These belts can reduce friction and heat, allowing machines to run more evenly, which means producing more products in a shorter time. This allows businesses to achieve production targets while staying within the budget. Plus, as high temp belts also prevent continuous maintenance and repairs, it can thus save cost and time for the company to concentrate on their job.