A special type of belt which is endless; as the name suggests, an anti tear steel cord conveyor belt are used to facilitate movement in factory and warehouse settings. Such belts play a significant role since they simplify the transportation of goods from one place to another, saving you time and effort. These belts are produced by Shandong Xiangtong Rubber Science. Depending on the purpose of the belt and its place applications, it can use various types of rubber for that.

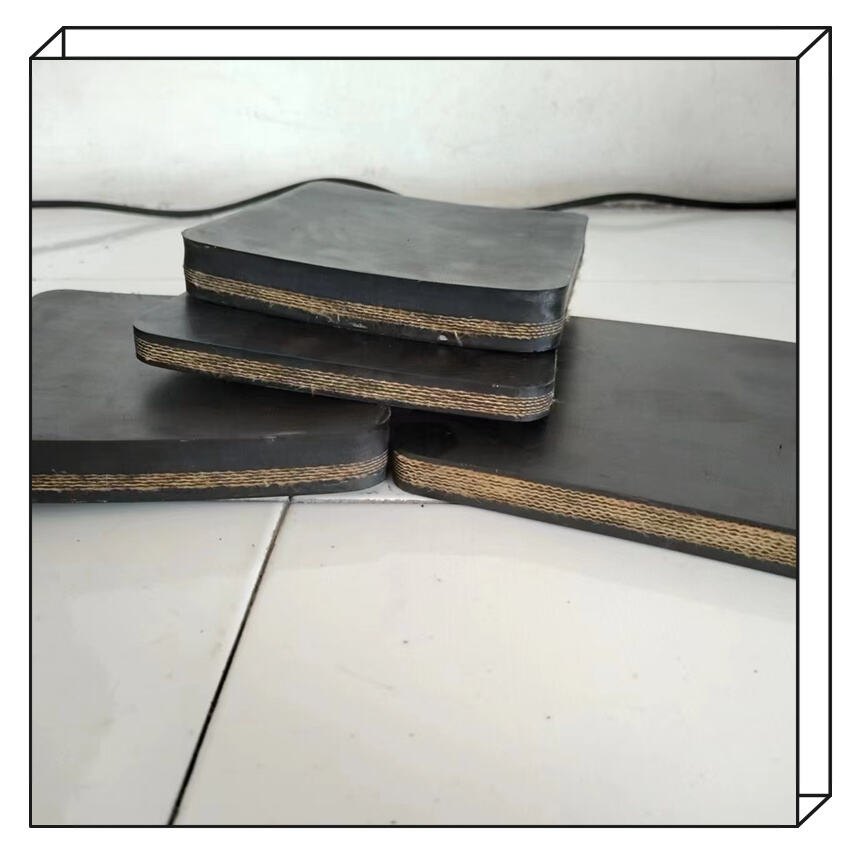

How endless rubber conveyor belts are made is pretty interesting. It is formed by joining the ends of a long rubber belt together. And no metal parts or fasteners were used to accomplish this. Rather, you sew the ends together to create a seamless loop. It means that the belt is smooth, without any bumps or breaks, and can thus transport items from one place to another with ease. This is a strong, heavy-duty belt that will not be damaged when it carries heavy items because that type of hardware contains no parts made of metal which can wear out or break.

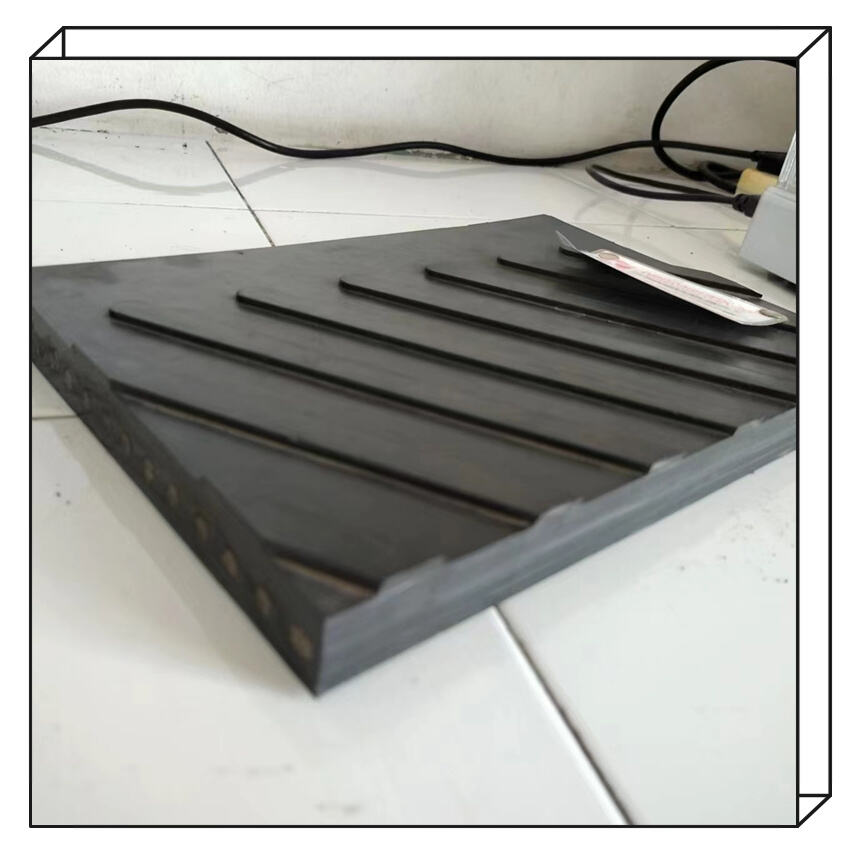

The thing I love most about using an assembly line conveyor systems is that it just works. These belts may be fashioned to suit exactly where it will go, regardless of whether this is a small space or perhaps an extra large spot. With years of experience, the professionals at Shandong Xiangtong Rubber Science work with businesses to equip them with an ideal conveyor belt design and setup for their individual needs.

The seemingly endless roll of rubber conveyor belting ensures that production will proceed unimpeded. It does so by minimizing the downtime when work is never being done on the machines. You have to make some repairs on these machines, and that can take a while. Shandong Xiangtong Rubber Science manufactures the types of belts that are intended to be effective over a long period, meaning that the need for repairs is infrequent. This has a big helps with less disruption.

In comparison with traditional conveyor belts which need a great deal of maintenance as well as parts substitutions made routinely, the endless rubber conveyor belt generally requires very few components to get replaced. This is extremely useful because the part replacement process is time-consuming and expensive. Employing an endless rubber conveyor belt saves time as well as money for businesses; they can now focus on their job rather than repairing.

There are so many benefits of rubber conveyor belts. The most important benefit is that they can carry them safely, transporting various types of materials. Rubber is a pliable material, which indicates it can bend and flex without easily cracking. It makes it an ideal option for harsh environments service using heavy machinery or has pointed tools that might deface the surface.

One more advantage of rubber conveyor belts is that this is light-weight in nature. Note that lighter belts utilize less energy in operation, reducing cost. They are also more manageable for workers as well, enhancing workplace safety. Rubber is another eco-conscious material. At the end of their lifecycle, rather than being thrown in a landfill these belts can be recycle and reused.