Conveyor Belts in Coal Mines: An Exploration of Their Role

Conveyor belts are a staple in coal mines, providing an excellent way to transport coal from one place to another. This paper covers the history of conveyor belt systems in underground coal mines and how they integrate with coal mines.

Evolution of Conveyor Belt Systems

The use of conveyor belt systems in underground coal mines started in the 1800s, during the late 19th century. Initially, the operation of conveyor belts was labor-intensive, requiring manual cranks to move coal.

In the 20th century, technological advancements revolutionized the coal mining industry. Conveyor belt systems became safer and more efficient with the introduction of powerful engines and electric motors.

Conveyor belt operations are crucial in coal mines, facilitating the movement of coal from extraction areas to processing facilities. Without conveyor belts, the extraction process would be slower and less efficient.

New conveyor belt solutions enable mining coal from deeper ground levels, leading to faster transportation and processing. These innovations boost mining company profits by increasing operational efficiency.

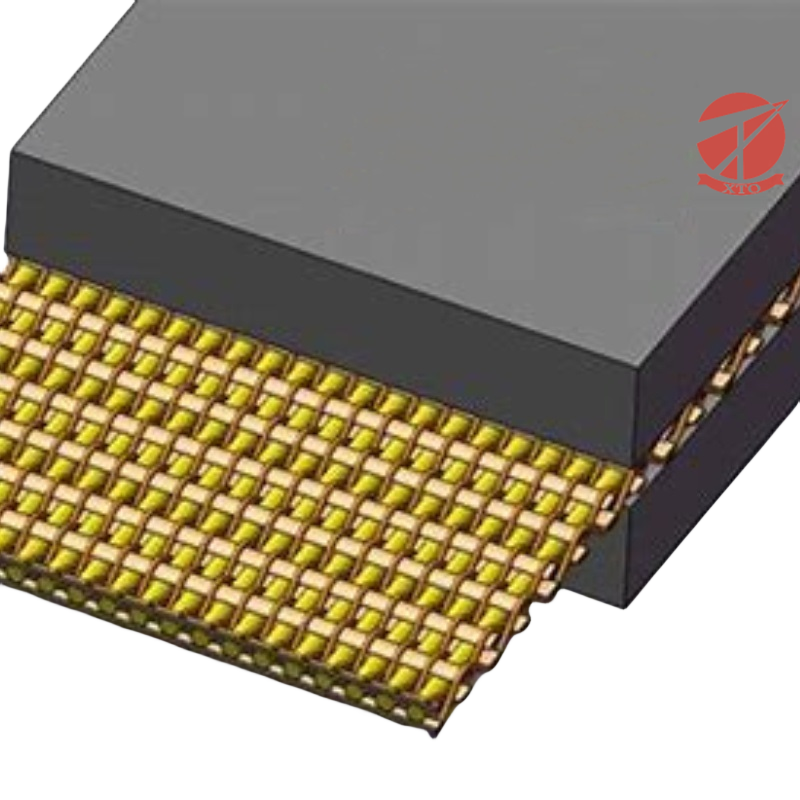

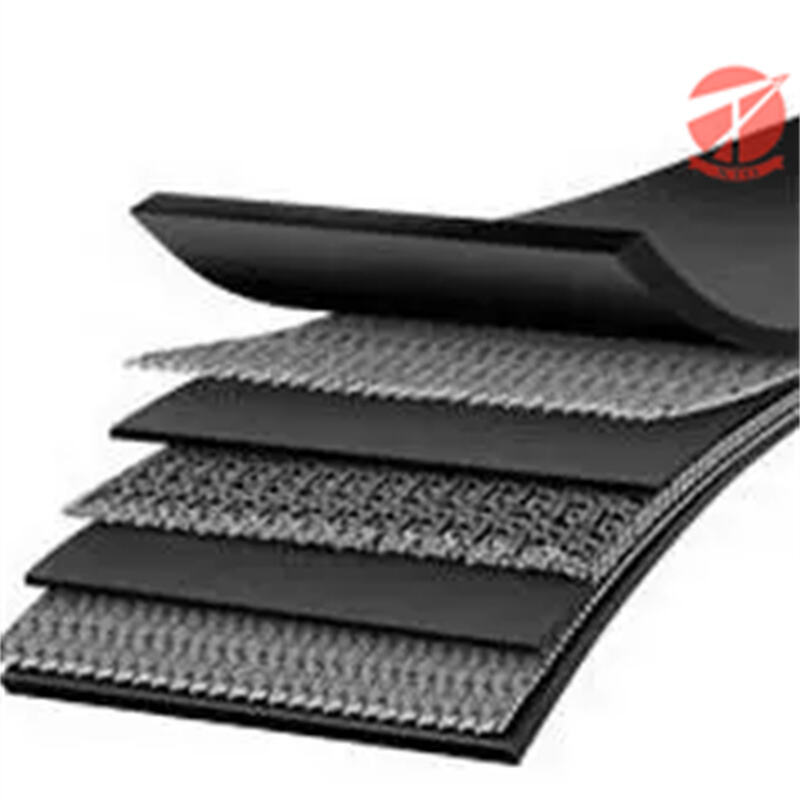

Modern conveyor belt designs prioritize durability and structural integrity to withstand harsh conditions in coal mines. They ensure efficient coal extraction while maintaining safety standards and overcoming operational hazards.

The product line includes conveyor belts made of steel, multi-ply textile belt, solid woven conveyor belt and sidewall belts, pipe belts, patterned belt, lifting belt and aramid conveyor belt. The annual design capacity of 29 million square meters of conveyor belts. Among the belts: We have 11 conveyor belts that are solid woven production lines, four multi-ply textile belt production lines, and seven conveyor belts produced by steel lines. We also have the longest steel conveyor belt vulcanization machine cold in conveyor belt in coal mines.

We have successfully passed the conveyor belt in coal mines standards of ISO9001, ISO14001, and ISO45001. In addition, our products have consistently been tested for quality by renowned organizations like RWE, TUV, BV, MSHA and MASC.

We have a highly skilled RD team with experts who are setting national standards. And we have obtained 32 national utility model patents like "multi-ply conveyor belt made of conveyor belt in coal mines" and has issued a total of 3 invention patents as well as 11 utility model patents such as ultra-wear resistant conveyor belt, and has partnered with a number of universities, which shows the company's leading position in rubber industry technology. We also have an extensive and efficient after-service team made up of 32 individuals.

The company boasts modern production equipment, professional management team, and top technology, so that the company has developed into a formidable competitive ability of the enterprise and the PVG conveyer belt holds the highest percentage of the conveyor belt in coal mines in China. We are vice-chairman in China's conveyor belt market and also one of the leading makers. The company was awarded the honor of "China Quality brand" and "The most important brand in the area of conveyor belt in China", etc.