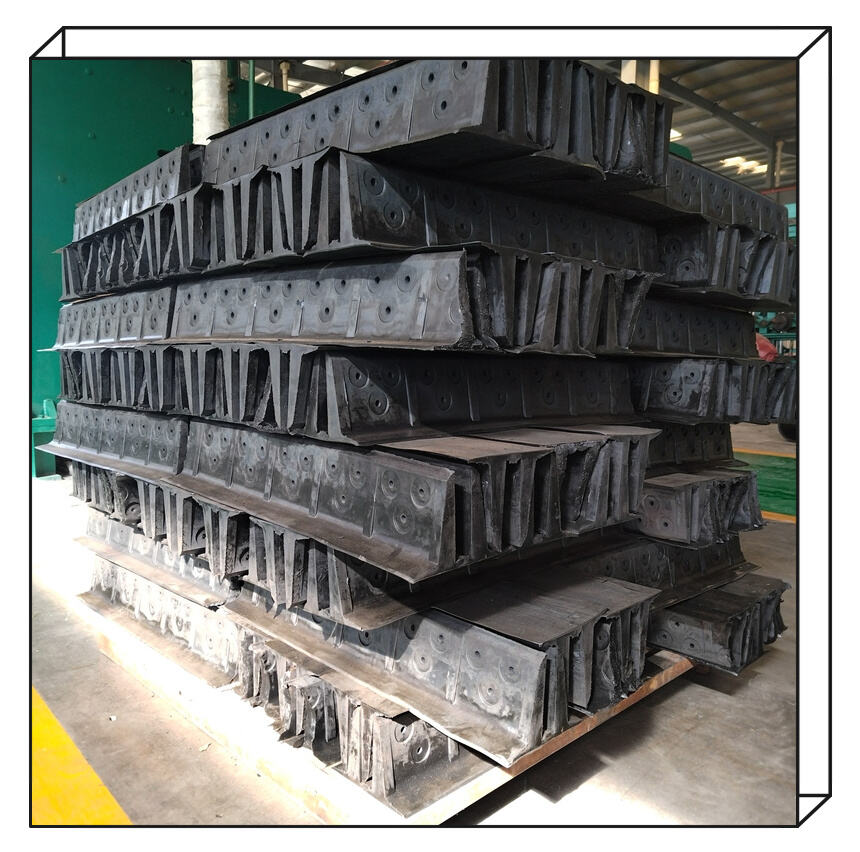

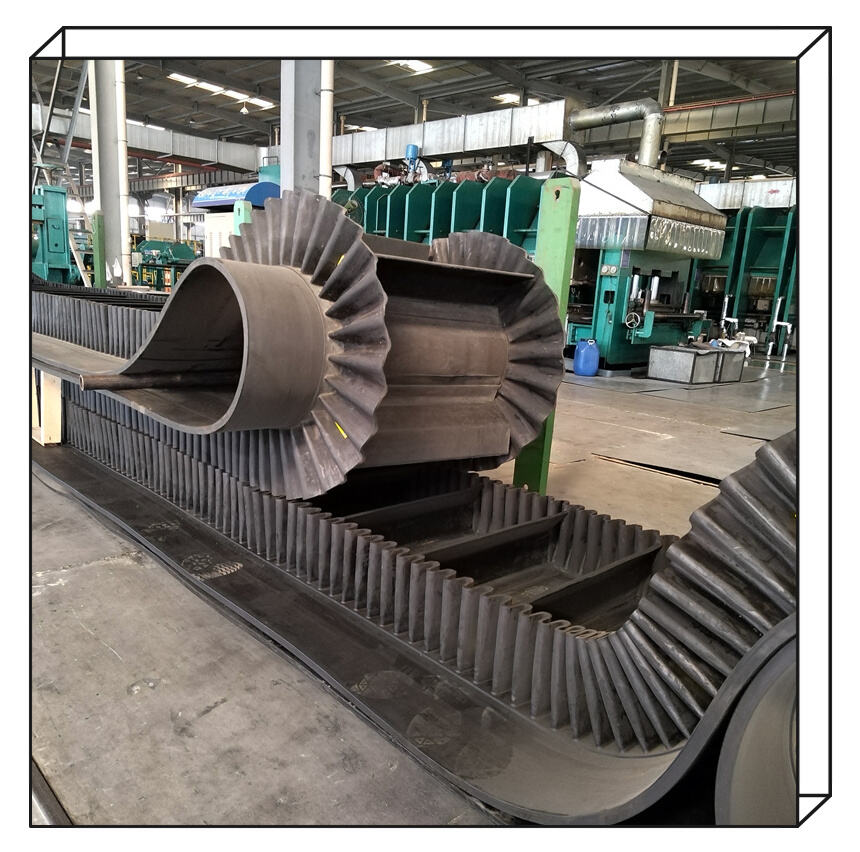

These are unique conveyor belts with cleats that easily and efficiently move heavy objects. These belts are large strips of flat,(think a big ribbon), those roll around wheels The belted ones feature cleats — that is, the plastic lugs that you see on standard conveyor belts. Cleats are small, step-like features that protrude from the belt surface. They enable to grip the materials being moved and help you push up or down along with conveyor. Cleats can appear in many differing forms, making them usable with multiple kinds of materials. That design also means that rubber cleated conveyor belt are simply easier and safer to use when transporting heavy loads.

Materials that has to be moved from one point to another like grains, rocks and chemicals. A lot of these substances can be extremely heavy and they are challenging to relocate. But cleated conveyor belts make this easier to do. The cleats on the belts form small pockets where the materials are allowed to rest during transit. These pockets make sure the materials in these do not slide or fall from the belt while being moved. Its innovative design enables the powerful movement of heavy materials in a manner that is faster, safer and more efficient making it easier to manage the whole process.

To be productive is to do something in the lowest or least time. Cleated conveyor belts are useful in increasing the productivity by transferring heavy materials faster than hand transfer. A conveyor belt allows workers to utilize the belt rather than having to lift large and heavy items on their own. This saves them plenty of time and work, allowing them to concentrate on the other necessary things they need to do. This way cleated belts work like maintainance robots that handle the hard carrying, leaving employees to focus on their role more effectively.

Each material has its own requirements when it comes to being moved. This is why you can find customizable cleat patterns with every cleated conveyor belt. Cleat size, shape and spacing can be tailored to the specific material being conveyed. Slippery materials might require taller and closer together cleats to grab the surface. Conversely, if heavier items are transported, it may require more separation between cleats to prevent damage. Such stuff has to be moved safely and effectively in order to reduce the risk of accidents and these custom cleats ensure that this is well done.

No One Wants a Broken Machine No One Ever Suspects of Being It, Especially Not When They Are Moving Heavy Materials Cleated conveyor belts manufactured of high calibre and long lasting process. They are made of sturdy materials that make them resistant to a great deal of wear and tear for many years. Moreover, these conveyor belts need almost close to no support which is a major benefit. These do not require extensive oiling or greasing, saving businesses time and money. For companies that regularly have to deal with heavy loads, a professionally exploited conveyor belt can last for years and years, which makes it a good investment.

When it comes to moving heavy materials, safety is always priority number one. Thankfully, cleated conveyor belts are engineered withSafetyat the very top of their design principles. Belt cleats hold the materials in place, preventing them from sliding or dropping off through transport. They are made from non-slip materials where conveyor belts will ensure that the workers will have a good footing when loading or unloading the materials. Another aspect that cleated conveyor belts are designed for is reliability, meaning fewer breakdowns and issues. It ensures the safe operation of workers near or around conveyor system.

Shandong Xiangtong Rubber Science is a manufacturer of cleated conveyor belts. They are aware of how unique different materials need to be treated and therefore provide tailor fitted cleat patterns. Shandong Xiangtong Rubber Science is a leading cleated conveyor belts manufacturer that specializes in strong and safe rubber products for effective and secure handling of heavy materials.