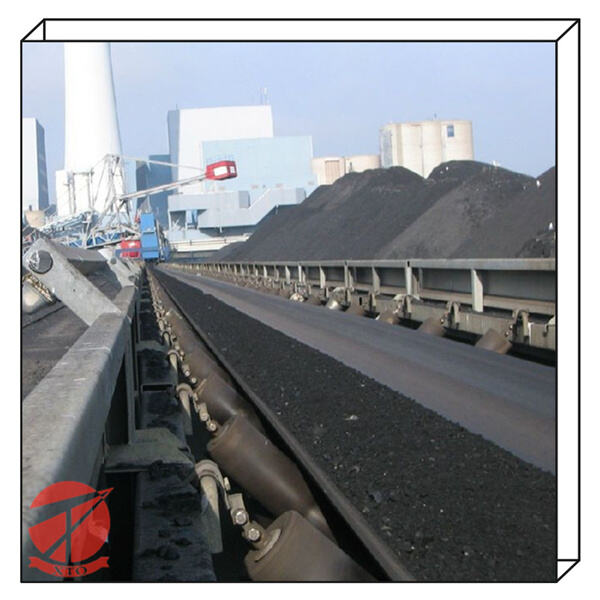

Underground Conveyor Belts are Lifeline of Mining Industry They assist in easy transportation of goods from one place to another. This makes collecting materials easier and quicker for the miners then taking it to surface to process or use. Long before conveyor belts, moving heavy materials had to have been a real pain without them.

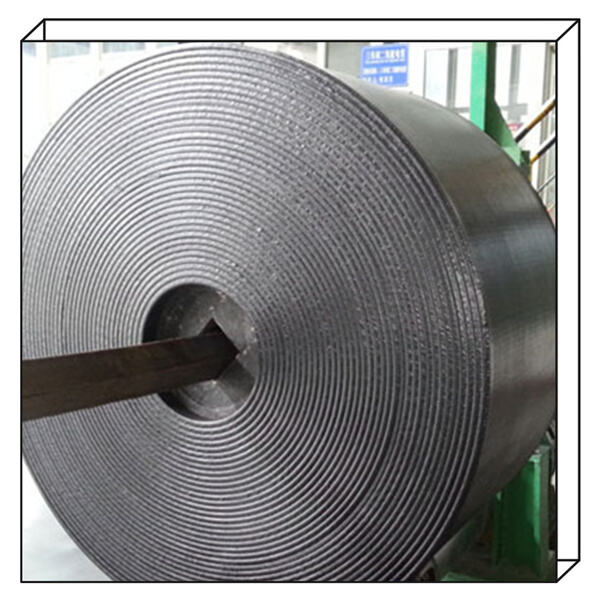

Given the tough and harsh conditions under which mining work is often done, strong reliable solutions are a must. Conveyor belts are designed to survive extreme conditions and given that some installations will be performed underground, an option suitable for industrial use is usually chosen. These are also heavy duty furniture, designed to withstand weather as well damage and wear of the life that you will put upon them. This does allow for the conveyor belt to keep working long-term, even when subject under difficult conditions.

Because underground conveyor belts are ideal in narrow and small spaces. Mines are relatively confined workplaces which can make material handling a challenge. Fortunately, the answer to this question is an easily solved one: a conveyor belt system capable of creating a continually cycling path that will move materials without requiring all of your available real estate.

The underground conveyor is bendable and therefore, it can be adapted to cater individual requirements. In other words, miners can install the conveyor in hard-to-reach areas. This way, they are saving lot of time and energy that is invested in moving the materials into or out from narrow spaces. In a busy mining operation where time is of the essence, this flexibility is invaluable.

In addition, the conveyor belt can also be placed at many strategic locations that allow it to funnel materials straight into where they need processing. Crucially, this also frees miners to concentrate on other important aspects of the mineral extraction process instead of constantly reloading ersatz mining-disposal equipment. As industrial sectors tend to have extremely tight deadlines, the whole process may be operated at an ease by streamlining it.

The conveyor belt technology is much advanced then before. Modern conveyor belts are using new age technologies and techniques thereby making mining work even better. This may include sensors on conveyor belts that can determine if materials are flowing properly and at the right rate. This ensures the conveyor belt operates as it should and provides information to improve its performance.

Some conveyers belts are equipped with sensors and others come with special software that keeps tracks of the way system is functioning. This tool is essential since by know problems before they occur it can alert the workers. Miners can thus prepare accordingly so that they fix things to avoid a situation where everything has stopped working as expected.