It can be a lot of work especially the moving of heavy things from one area to another. Getting things where we want them to go usually takes a lot of time, sweat and tears. However, a job like this is becoming easier and faster with new technology such as the PVG 1400S conveyor belt. PVG 1400S is employed by several factories to aid in moving goods from a particular sector of the factory to another. A lengthy, stretchy belt which can carry significant weight loads conveying benefits as well. The PVG 1400S conveyor belt allows material to be moved quickly which enables factories to run smoothly and more productively.

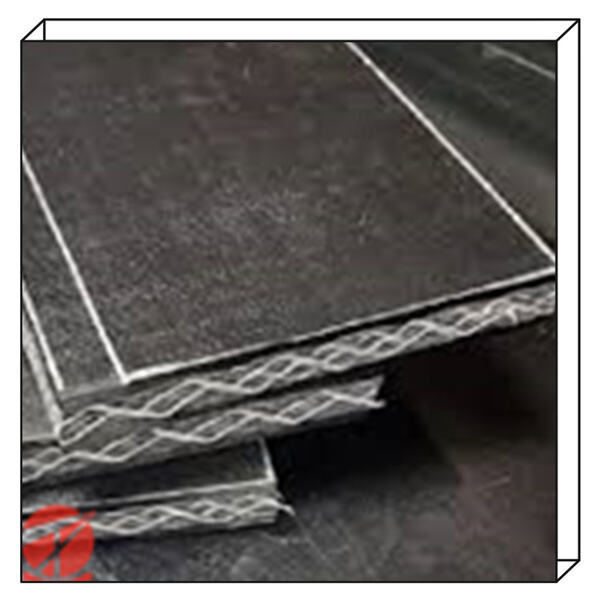

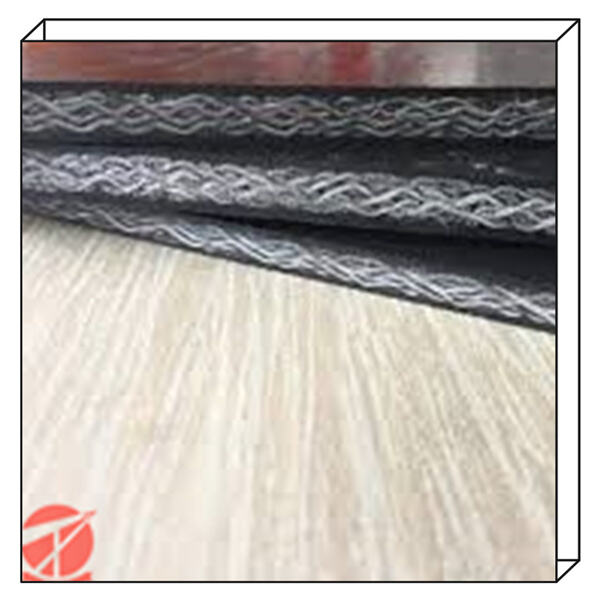

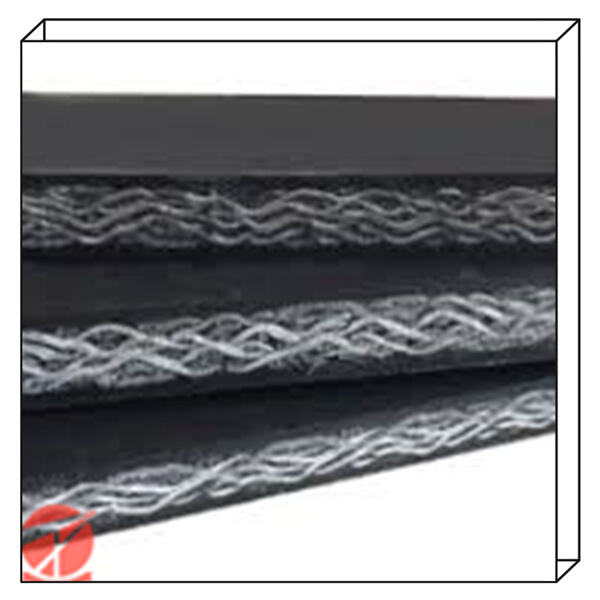

The conveyor belt PVG 1400S is produced specifically from small parts of plastic, which are connected with durable metal pins. These are able to bend and flex, which is required when the belt needs to move around corners or in different directions. The flexibility is important because factories depending on the layouts will need to move items different ways. All the metal pins keep everything together, making a solid surface that can hold with heavier stuff without damaging.

Factory used conveyor belt Belt Conveyor PVG1400S It can be seen, for example in a food processing plant or car factory and even at airports. Fruits and vegetables like in food processing plants lean on it to move from one place to another faster. It is beneficial in car factories for moving parts from one station to another, which helps accelerate the production. And at airports, it transports baggage from check-in right to the aircraft without fussing about where those bags should be by when.

Smooth Operation:The PVG 1400S conveyor belt runs smoothly and efficiently. These plastic pieces are located far enough apart so that the jogger can move comfortably. This allows for products to slide on the belt without stalling. The metal pins also contribute in it to reduce friction, that is belt can move easily without much of force.

Safety is the utmost priority with a PVG 1400S conveyor belt. And when they're working near the belt, it has smooth edges that can be less of a hazard than if you have zinc plated or something with an exposed sharp edge. Since the belt has no sharp edges, it is less likely to injure workers. The belt also contains a series of emergency stop buttons at various points along its length. That way its easy to stop the belt if there is any emergency or some issue.

How about the PVG 1400S-conveyor belt-based in long term reliability. The plastic pieces are more shock resistant, which means the belt can last for a longer time than if you use paper. It is also highly cleanable, making it ideal in the food processing plants where cleanliness may be paramount.

If a plastic piece is damaged, only that part can be replaced without having to change the whole belt. This comes with a huge advantage as you save on time and money. The conveyor belt is adjustable to meet the needs of different factories, so there are many uses for this equipment.